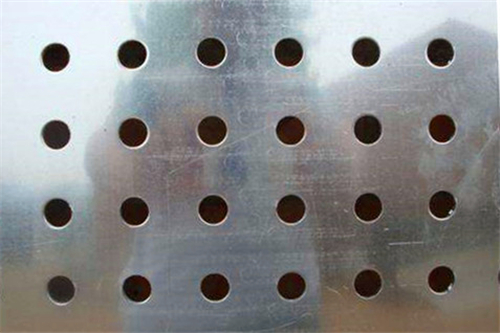

How to Prevent Perforated Sheets from Rusting and Corrosion

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 16:05:40 Browse:

Perforated sheets are made from metal materials such as iron, aluminum, and stainless steel. Among these, stainless steel perforated sheets naturally resist corrosion and do not rust. Therefore, the main focus of rust prevention lies in iron and aluminum perforated sheets. Below are specific methods for preventing rust:

Rust Prevention for Iron Perforated Sheets

1. Short-Term Storage Protection

For short-term storage, applying anti-rust oil to the surface of iron perforated sheets can effectively prevent corrosion.

2. Surface Treatments

Painting: Applying anti-rust paint creates a protective layer on the sheet surface, isolating it from moisture and oxygen in the air, thereby reducing the likelihood of rusting.

Electrostatic Powder Coating**: This method not only provides effective rust prevention but also allows for color customization, enhancing the decorative appeal of the perforated sheet.

Rust Prevention for Aluminum Perforated Sheets

Painting or Powder Coating

1. Aluminum perforated sheets can be treated with paint or powder coatings to form a protective layer. This layer helps prevent corrosion and offers various color options to meet different aesthetic requirements.

2. Anodizing

Anodizing is a critical anti-corrosion method for aluminum perforated sheets. By forming a dense oxide film on the sheet's surface, anodizing significantly improves corrosion resistance, enhances wear resistance, and extends the sheet's service life.

By implementing these methods, rust and corrosion issues in perforated sheets can be effectively minimized, improving their functionality and visual quality.