Detailed Analysis of the Applications of Perforated Metal Sheets in Various Fields

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-04 14:58:05 Browse:

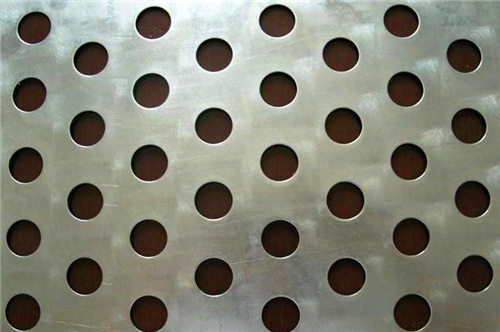

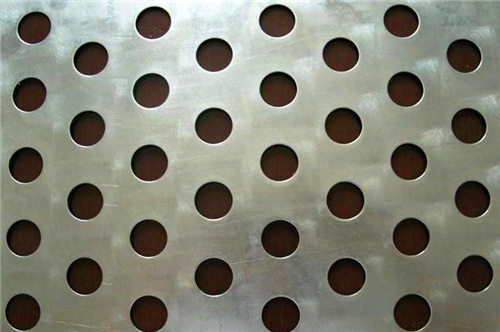

Perforated metal sheets, due to their unique hole design and multifunctionality, play an irreplaceable role in multiple fields such as industry, construction, and home decoration. This article will delve into the main application areas of perforated metal sheets, including decorative perforated sheets, filtering perforated sheets, and functional perforated sheets, and provide a detailed explanation of their advantages and future development.

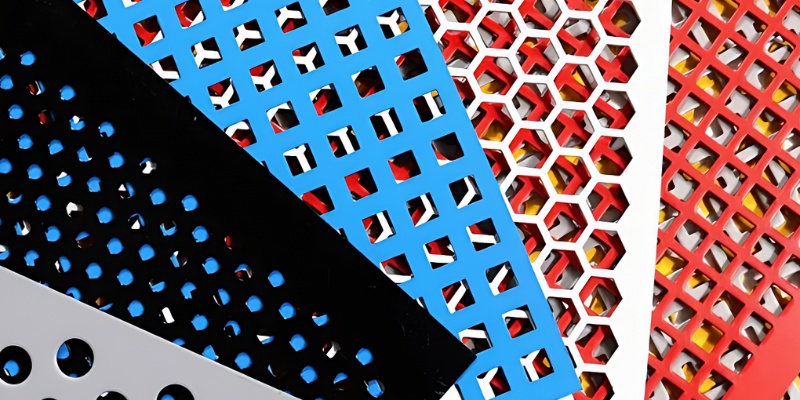

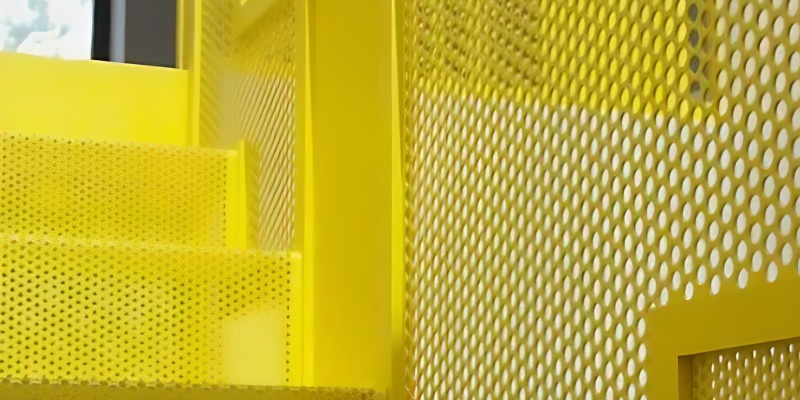

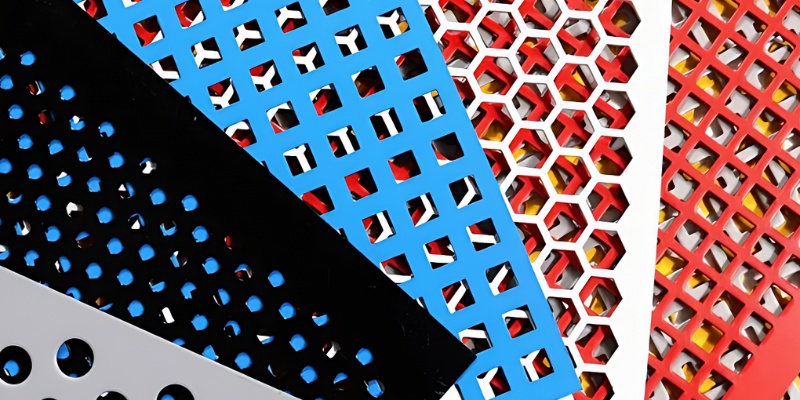

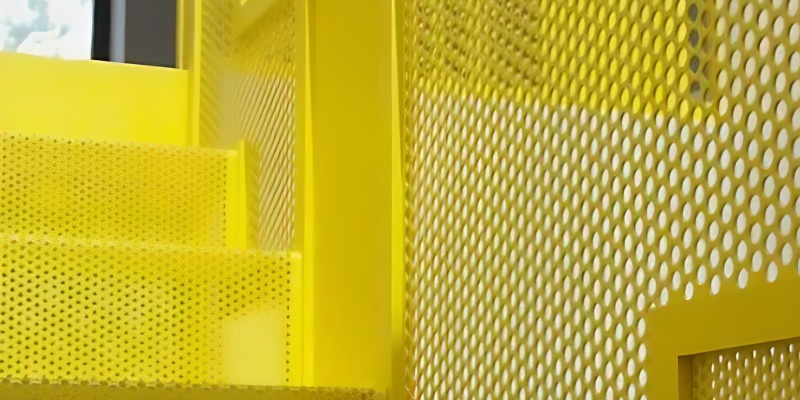

Application of Decorative Perforated Sheets Decorative perforated sheets are characterized by both aesthetics and practicality and are widely used in the following scenarios:

Indoor and outdoor architectural decoration: In ceilings, indoor partitions, building exteriors, and facades, perforated sheets not only separate spaces and create artistic atmospheres but also effectively absorb noise, enhancing the overall comfort of the space.

Transportation facilities: In sound barriers along highways and railways, decorative perforated sheets can effectively reduce noise pollution, improving the travel experience for residents and passengers.

Home and commercial equipment: For example, speaker grilles in audio equipment, car air intake grilles, and cooling screens of various mechanical devices, which meet functional requirements while also having decorative effects.

The diversity of perforated metal sheets in the decorative field not only enhances the visual effect of buildings and equipment but also emphasizes practicality, offering users higher cost-effectiveness.

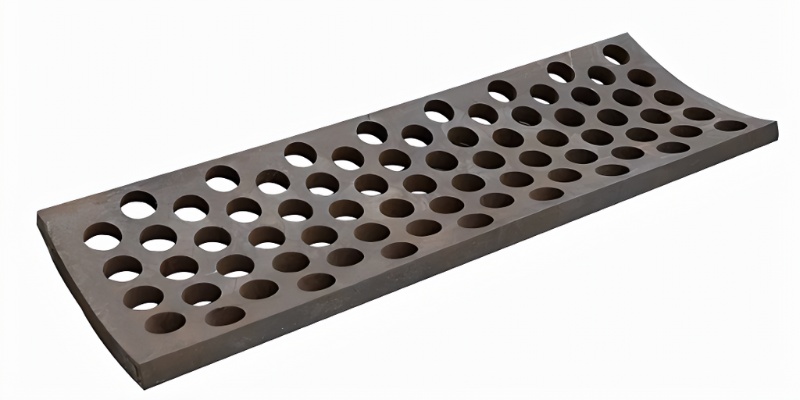

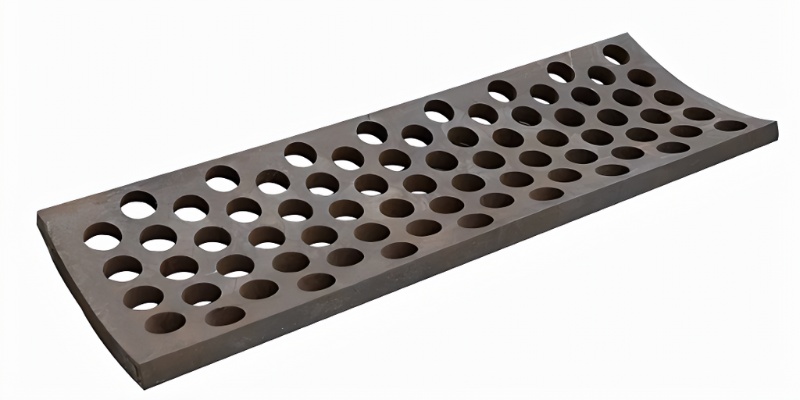

Application of Filtering Perforated Sheets Filtering perforated sheets, with their precise hole diameter control and durability, have irreplaceable advantages in fine sieving and material filtration, mainly including:

Machinery and chemical equipment: As sieve plates in crushers, chemical machinery, and pharmaceutical equipment, they effectively achieve uniform grading and fine screening of materials.

Food and beverage processing: In the production process of food and beverages, perforated sheets can efficiently filter impurities, ensuring product hygiene and quality.

Other industrial fields: For example, in papermaking, hydraulic systems, and tobacco machinery industries, perforated sheets serve as filters, ensuring stable operation of equipment and product quality.

With high-precision manufacturing processes and excellent corrosion resistance, filtering perforated sheets demonstrate outstanding filtration efficiency and durability in many industrial applications.

Application of Functional Perforated Sheets Functional perforated sheets are not limited to decoration or filtration; their unique design makes them widely used in daily life and commercial applications, such as:

Commercial display and exhibition: In shopping malls, exhibition halls, etc., perforated sheets are often used as display cabinets, shelf back panels, or decorative screens, being both beautiful and practical.

Agriculture and storage: Used in grain warehouse ventilation, drainage, and filtration and protection equipment for agricultural products, perforated sheets help maintain dry and clean environments.

Household items: For example, fruit baskets, food covers, and various storage racks in kitchens, which are not only convenient and practical but also add a modern touch to the home environment.

Through flexible and diverse design schemes, functional perforated sheets meet the needs of different fields while continuously expanding their application space in emerging markets.

Advantages and Development Trends of Perforated Metal Sheets Summary of advantages:

Multifunctionality: Whether for decoration, filtration, or other functional applications, perforated metal sheets can be customized with different hole patterns and specifications according to customer needs.

Durability and stability: Made from high-quality metal materials and advanced manufacturing processes, they possess excellent corrosion resistance, wear resistance, and pressure resistance.

Energy-saving and environmental protection: In architectural soundproofing, equipment heat dissipation, and industrial sieving processes, perforated sheets can effectively improve energy utilization rates and reduce environmental pollution.

Future development trends:

Smart customization: With the growing market demand for personalized designs, perforated metal sheets will develop towards higher precision and smarter customization.

Green manufacturing: Under the impetus of environmental policies, future production of perforated metal sheets will focus more on energy conservation, emission reduction, and sustainable development.

Application of new materials and processes: Continuously introducing new materials and advanced processes not only improves the performance of perforated sheets but also broadens their application scope in emerging fields.

Summary Perforated metal sheets, with their unique hole design and diverse applications, have become an important component in the fields of construction, industry, and home. Whether in decorative effects, noise control, or filtration and sieving, they exhibit excellent performance and broad application prospects. With continuous technological progress and market demand upgrades, perforated metal sheets will undoubtedly play a greater role in more fields, becoming an important force driving industry innovation and development.

By continuously optimizing product performance and process levels, we are committed to providing customers with high-quality, high-cost-effective solutions for perforated metal sheets. We welcome all customers to consult and cooperate, jointly exploring the applications and innovations of perforated metal sheets in various industries.