Why Stainless Steel Perforated Sheets May Have Slight Deformation After Production

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-01-10 13:51:00 Browse:

The slight deformation that occurs in stainless steel perforated sheets after production is typically the result of multiple factors. First, stainless steel perforated sheets are produced through continuous punching on a precision CNC punching machine, using stainless steel sheets and customized molds. During the punching process, the force exerted by the punch changes the internal stress of the stainless steel sheet. The deformation becomes more pronounced when the distance between two holes is smaller, as the stress distribution becomes more concentrated.

Secondly, during production, the material undergoes elastic deformation. While the perforated sheet is formed after punching, the internal stress generated during the punching process is not fully released, causing slight deformation as the material cools. This deformation is more noticeable when the hole spacing is very small, as the forces are more concentrated in these areas.

To address this issue, stainless steel perforated sheets are typically corrected for flatness using a flatness corrector. In most cases, the flatness corrector can effectively straighten the perforated sheet and restore its flatness. However, for sheets with very small hole spacing, slight deformation may still remain even after flatness correction. This occurs because the internal stress distribution within the material may prevent it from fully returning to an ideal flat state, even after correction.

In summary, slight deformation is a common occurrence during production, especially when the punching density is high or the hole spacing is small. In most cases, flatness correction can significantly improve this issue, but under extreme conditions, some perforated sheets may still exhibit slight deformation.

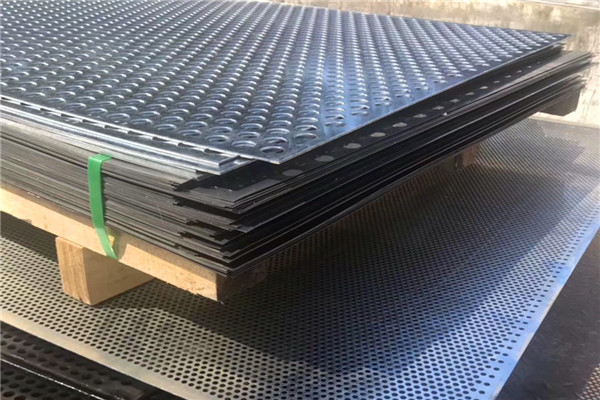

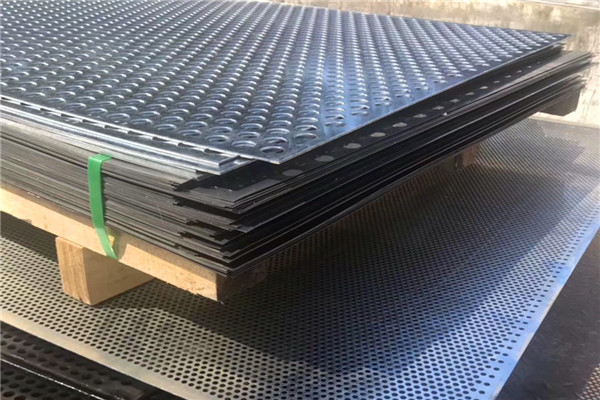

Stainless steel perforated sheet