Galvanized Perforated Sheet – Specifications, Customization, and Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-01-10 14:10:00 Browse:

Galvanized perforated sheets are a versatile and durable material used across a wide range of industries, including construction, machinery, decoration, transportation, and more. These sheets are made from steel or other metals and are coated with a layer of zinc to enhance corrosion resistance and extend their lifespan. The "perforated" part refers to the various holes punched through the sheet in different patterns and sizes. These perforated sheets offer excellent functionality, combining aesthetics with practicality. Below, we’ll go into detail about the various specifications of galvanized perforated sheets, customization options, and their applications.

1. Common Specifications of Galvanized Perforated Sheets

The specifications of galvanized perforated sheets cover several key areas such as sheet thickness, hole size, hole spacing (pitch), sheet size, and coating thickness. Here’s a breakdown of these specifications:

(1) Sheet Thickness

The thickness of galvanized perforated sheets typically ranges from 0.5mm to 8mm, with common thicknesses being 1.0mm, 1.5mm, 2.0mm, and 3.0mm. The specific thickness is chosen based on the sheet’s intended use:

Thin sheets (0.5mm to 1mm) are commonly used for decorative purposes or applications that require lighter material.

Thicker sheets (above 2mm) are typically used for structural or load-bearing applications, offering more strength and durability.

(2) Hole Diameter and Hole Spacing (Pitch)

One of the defining characteristics of galvanized perforated sheets is the pattern of holes. The hole diameter can range from 1mm to 20mm or more, depending on the application. The spacing between the holes (the pitch) can also vary to suit the required functionality. Common hole diameter and pitch combinations include:

1mm hole diameter, 1mm pitch

1.5mm hole diameter, 1.5mm pitch

2mm hole diameter, 2mm pitch

3mm hole diameter, 3mm pitch

5mm hole diameter, 3mm pitch

8mm hole diameter, 4mm pitch

10mm hole diameter, 5mm pitch

20mm hole diameter, 10mm pitch Additionally, different patterns of hole spacing can be designed to suit specific purposes, such as:

1 hole 1 distance, 2 hole 2 distance, etc.

Rectangular, square, triangular, hexagonal patterns.

The choice of hole diameter and pitch will affect the material’s transparency, ventilation, strength, and aesthetic appearance. Different applications may require specific hole sizes and patterns.

(3) Sheet Size

Galvanized perforated sheets are generally available in standard sizes such as:

1000mm x 2000mm

1219mm x 2438mm However, these sheets can be custom-cut to meet specific requirements. Standard customizations typically include widths up to 1.5 meters and lengths up to 4 meters. For larger projects or specialized requirements, sheets can be manufactured to custom sizes.

(4) Galvanization Thickness

The thickness of the zinc coating applied to the perforated sheet plays a crucial role in its corrosion resistance. The galvanization thickness typically ranges from 30g/m² to 275g/m², with thicker coatings providing greater protection against corrosion. The right choice of galvanization thickness depends on the environment where the perforated sheet will be used, such as:

Light galvanization for indoor or less corrosive environments.

Heavy galvanization for outdoor use or areas exposed to harsh weather conditions.

2. Customization Services for Galvanized Perforated Sheets

In addition to standard specifications, galvanized perforated sheets can be customized to meet specific needs. Here are some of the available customization options:

(1) Custom Sheet Size

While standard sheets are available in specific dimensions, custom sizes can be provided upon request. This includes:

Custom sheet widths (up to 1.5 meters) and lengths (up to 4 meters), to suit different projects.

Sheets can also be cut to specific shapes (rectangular, circular, etc.) based on customer specifications.

(2) Custom Hole Patterns

Galvanized perforated sheets can be customized with a variety of hole shapes and arrangements. Some of the most common hole shapes include:

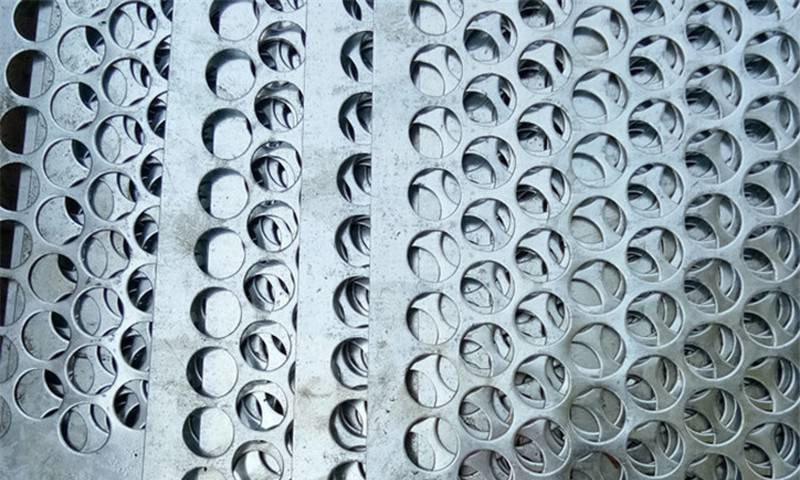

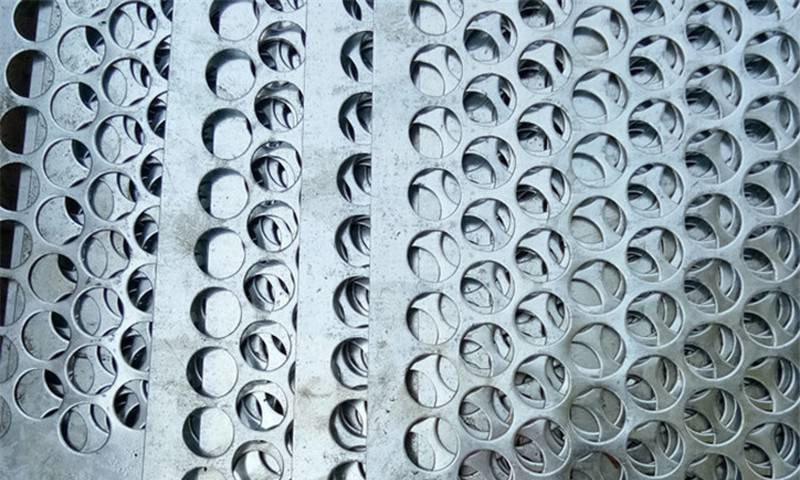

Round holes

Oval holes

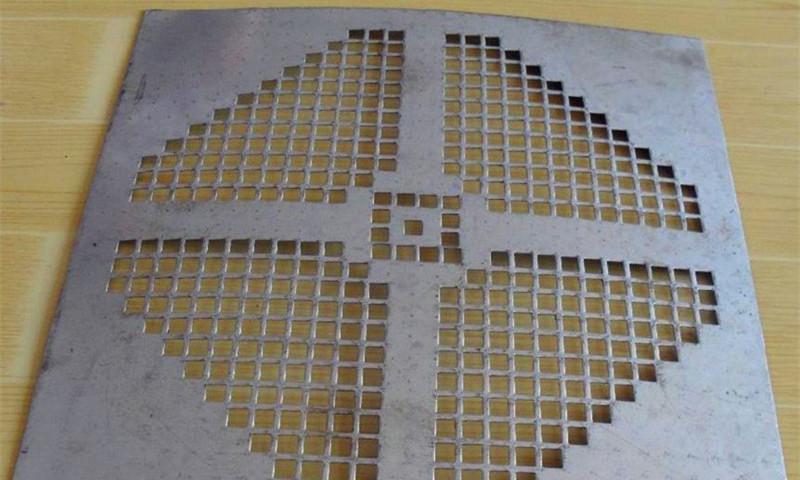

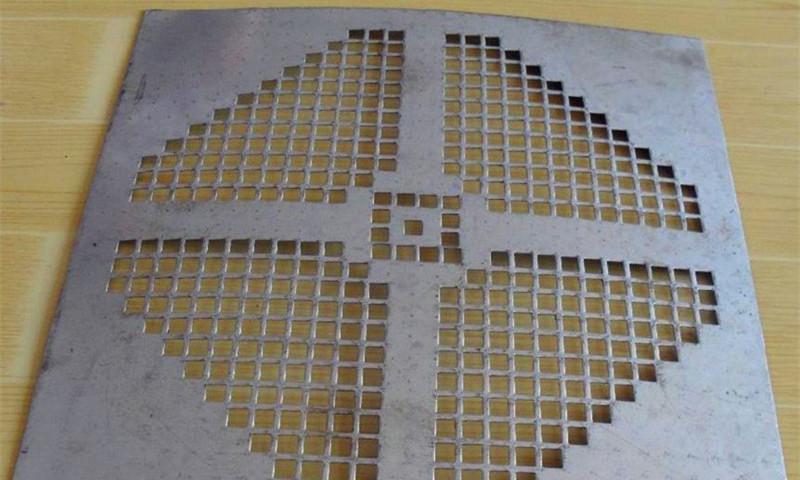

Square holes

Triangular holes

Star-shaped holes, hexagonal holes, octagonal holes, cross-shaped holes

Plum-shaped holes, fish-scale holes, diamond holes, louver holes, etc.

The spacing (pitch) of holes can also be customized to ensure the sheet performs as required for the specific project. Whether you need a high open area for ventilation or a low open area for strength, the hole pattern and spacing can be tailored accordingly.

(3) Surface Finishes

Apart from the standard galvanization, galvanized perforated sheets can be treated with other finishes to enhance their aesthetic appearance or durability. Common finishes include:

Powder coating: Provides an attractive, smooth surface and additional protection against corrosion.

Spray coating or painted finishes: Offers color options and extra protection against environmental factors.

Anodizing: A treatment that enhances surface hardness and wear resistance for certain types of metals.

3. Applications of Galvanized Perforated Sheets

Galvanized perforated sheets are used in a variety of industries for both functional and decorative purposes. Below are some of the most common applications:

(1) Construction and Architecture

In the construction industry, galvanized perforated sheets are widely used for:

Facade panels, curtain walls, and architectural cladding.

Ceilings, partitions, and exterior designs. The combination of durability, aesthetic appeal, and functional properties like ventilation and light filtration makes these sheets an ideal material for modern building designs.

(2) Transportation and Infrastructure

Galvanized perforated sheets are commonly used in:

Bridges and railway stations.

Airport terminals, bus shelters, and other public transport infrastructures. They provide excellent ventilation, strength, and aesthetic appeal in high-traffic or harsh weather environments.

(3) Machinery and Equipment

These perforated sheets are also used extensively in machinery and equipment manufacturing:

Protective enclosures, filters, and fan guards.

Cooling and ventilation applications, such as heat exchangers and radiator covers. They help improve airflow, cooling efficiency, and provide mechanical protection for sensitive components.

(4) Environmental and Filtration Applications

In industries related to environmental protection and filtration, galvanized perforated sheets are utilized for:

Air filtration and water filtration systems.

Gratings and separation systems in waste management, purification plants, etc. The perforations in the sheet ensure the efficient flow of fluids or gases while providing structural integrity.

4. How to Order Galvanized Perforated Sheets

If you are interested in purchasing galvanized perforated sheets or need more information, you can contact us via email or phone with your specifications. Please provide details such as:

Desired sheet size.

Required hole shape and spacing.

Thickness and galvanization requirements. Our professional team will promptly assist you with product information, provide a quote, and ensure that the perforated sheets meet your project needs. We also offer custom design services to provide tailored solutions for your specific requirements.

Conclusion

Galvanized perforated sheets are highly versatile materials with a wide range of applications. Their combination of strength, aesthetic appeal, and customizability makes them an excellent choice for various industrial, architectural, and environmental purposes. Whether you need standard or custom solutions, galvanized perforated sheets can meet the requirements of your project with ease. Contact us today to learn more and get a personalized quote!