3. Advanced Manufacturing and Customization

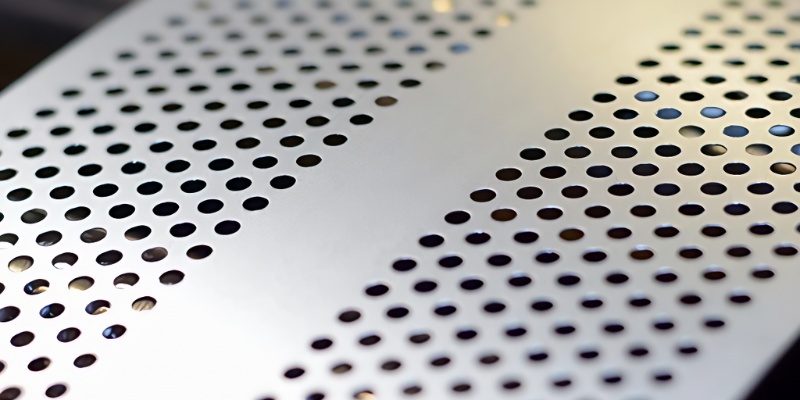

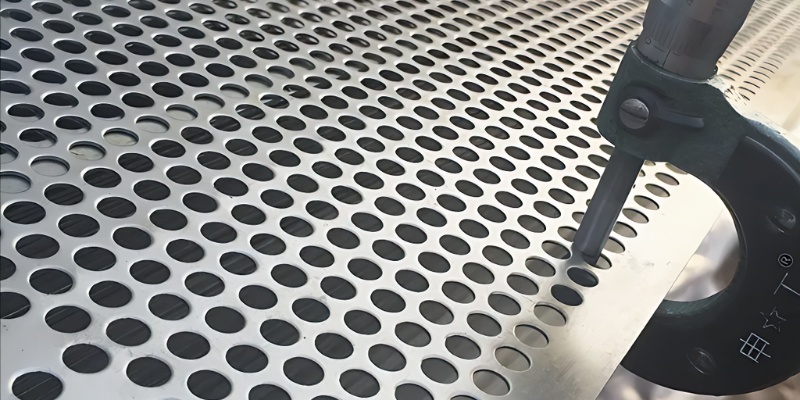

Using high-precision CNC punching technology, we ensure that every stainless steel perforated sheet meets strict quality standards. Our manufacturing capabilities allow us to create intricate patterns with consistent hole alignment and smooth edges.

Key customization options include:

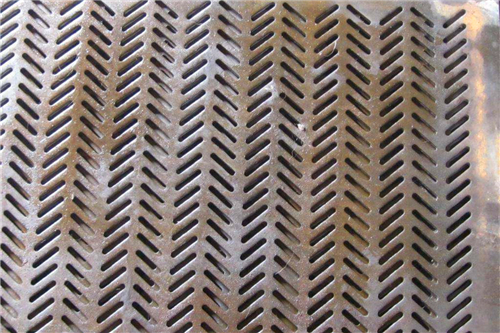

Custom hole shapes and patterns

Adjustable hole diameters and spacing

Various sheet thicknesses and dimensions

Surface treatments for enhanced durability

Our commitment to high-quality materials and advanced production techniques ensures that we deliver stainless steel perforated sheets that meet both functional and aesthetic requirements.

4. Applications of Stainless Steel Perforated Sheets

With their versatility, durability, and customization options, stainless steel perforated sheets are widely used in various industries, including:

Architectural & Decorative Applications

Used for facades, partitions, ceilings, and wall cladding, enhancing the visual appeal of modern structures.

Industrial & Filtration Applications

Applied in machinery guards, protective barriers, ventilation systems, and industrial filtration to improve airflow and safety.

Automotive & Transportation

Commonly used in grilles, soundproofing panels, and exhaust systems for enhanced aerodynamics and durability.

Public Infrastructure & Urban Design

Utilized in public building facades, railings, and noise barriers, combining functionality with aesthetics.