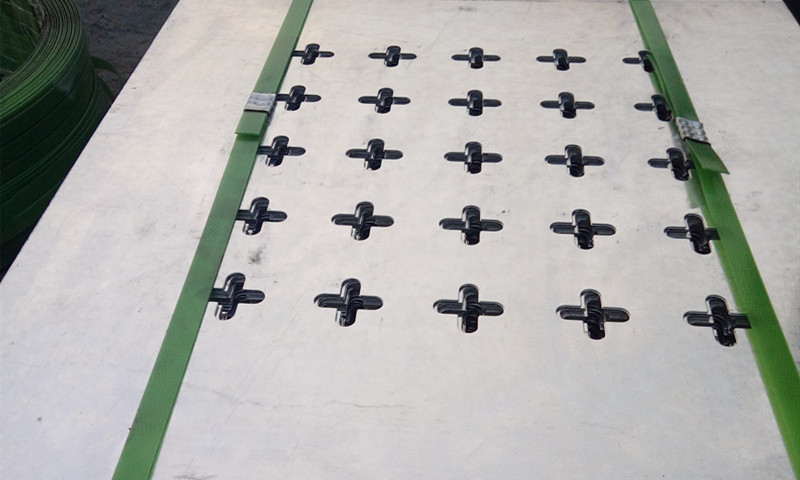

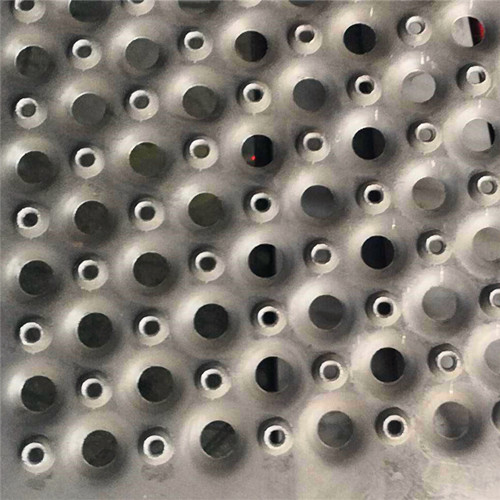

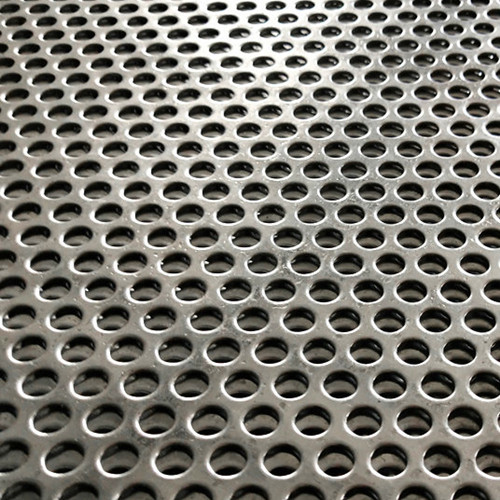

Cross hole iron plate perforated sheet is a mesh product manufactured by continuously punching high-quality iron plates using CNC punch presses with customized molds. Its unique cross-shaped hole design provides both functionality and aesthetic appeal. The product features a smooth, flat surface and durable construction, making it suitable for various applications.

It is widely used in transportation and municipal facilities, such as noise barriers for highways, railways, and subways. Additionally, it is effective for sound insulation and noise reduction in building walls, generator rooms, and factory workshops. Beyond its noise control capabilities, it can also be applied as decorative panels, ventilation sheets, or protective screens.

Applications of Cross Hole Iron Plate Perforated Sheet

Construction Industry:

1.Wall decoration, ceiling panels, and protective railings.

2.Noise insulation panels or ventilation panels, enhancing the functionality and comfort of buildings.

Transportation and Municipal Facilities:

1.Noise barriers for highways, railways, and subways.

2.Protective screens and ventilation panels in municipal projects.

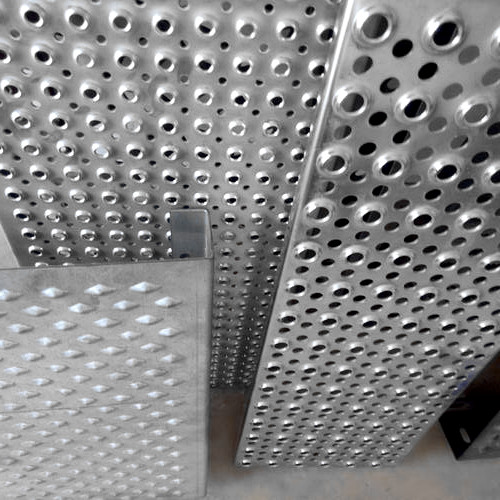

Industrial and Mechanical Use:

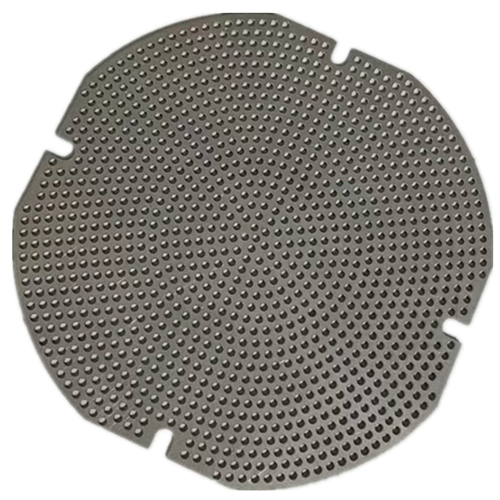

1.Used as sieves and filters in mining, metallurgy, and chemical industries.

2.Protective covers or ventilation systems in machinery.

Agriculture and Horticulture:

1.Ventilation or separation nets to improve agricultural efficiency.

Advantages of Cross Hole Iron Plate Perforated Sheet

1. High-Quality Materials: Made from premium-grade iron plates, ensuring durability and strength.

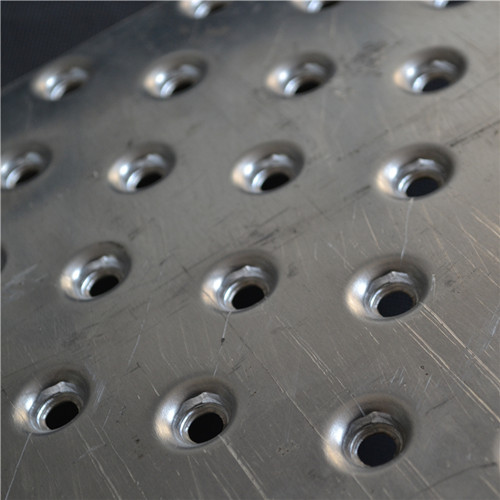

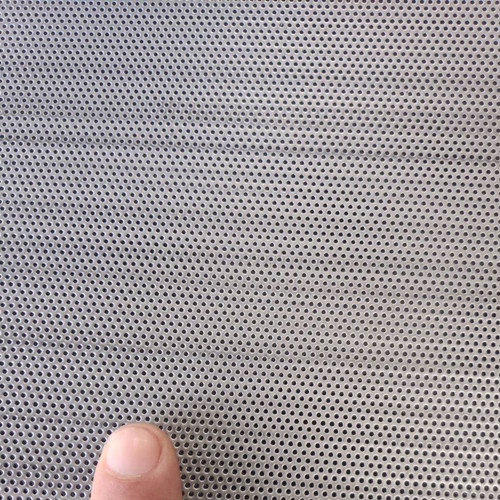

2. Precision Manufacturing: Produced using CNC punch presses, ensuring uniform hole distribution and excellent surface flatness.

3. Diverse Surface Treatments: Options include painting, powder coating, or galvanizing to enhance corrosion resistance and extend product life.

4. Customizable Solutions: Flexible specifications and design customization to meet diverse customer requirements.

Pricing Details of Cross Hole Iron Plate Perforated Sheet

The price of cross hole iron plate perforated sheets depends on several factors, including material type, thickness, size, hole diameter, and surface treatment:

1. Material: Cold-rolled plates are more economical, while galvanized and manganese steel plates are slightly costlier but offer superior performance.

2. Thickness and Size: Greater thickness and larger dimensions result in higher costs.

3. Surface Treatment: Painting and powder coating are moderately priced, while galvanizing is slightly higher due to its enhanced corrosion resistance.

For detailed pricing or more product information, please contact our customer service team via email or phone.

Contact Us

We sincerely invite customers worldwide to collaborate with us and promote the development of the perforated sheet industry. Feel free to contact us through the following methods:

Email: 342096438@qq.com

Phone: Please include your requirements in the email, and we will respond promptly.