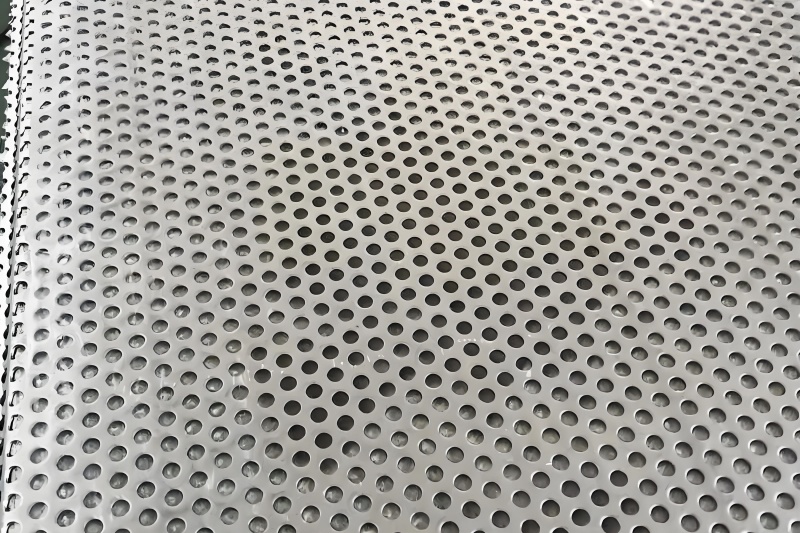

Features of Muffled Perforated Plates:

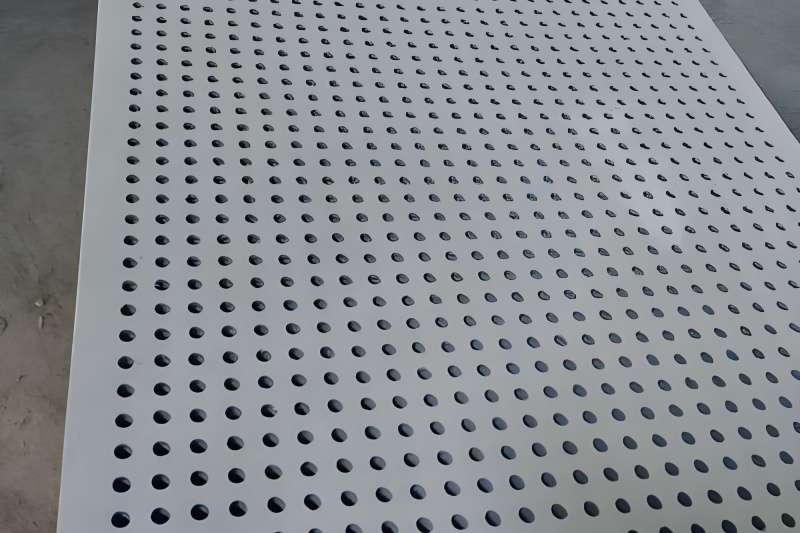

Customized Processing:

Muffled perforated plates can be tailored to the user’s needs, including size, thickness, material, hole size, and hole type. We offer flexible customization options to ensure each plate perfectly meets the specific requirements of your project.

Variety of Specifications and Materials:

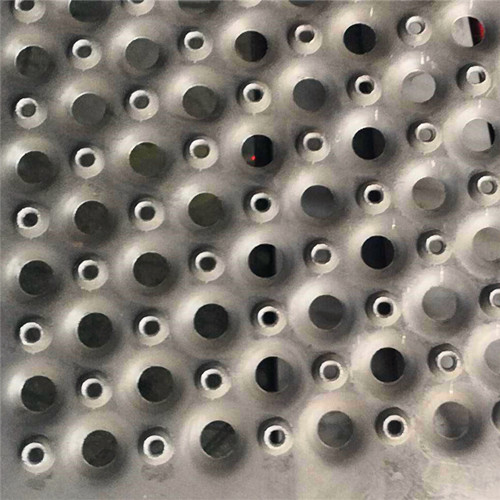

We offer a wide range of specifications and models for muffled perforated plates. Customers can choose from different plate thicknesses (0.1mm-20mm), materials (cold-rolled steel, hot-rolled steel, galvanized steel, aluminum, stainless steel, etc.), and hole types (round holes, oval holes, square holes, triangular holes, star-shaped holes, etc.), each providing different noise control effects.

Efficient Noise Reduction:

The muffled perforated plates are designed with precise hole patterns and made from high-quality materials, ensuring effective noise reduction to improve the working environment. These plates are widely used in noise-sensitive environments like mechanical equipment, building walls, and transportation infrastructure.

Multiple Surface Treatments:

Our muffled perforated plates come with various surface treatments, such as spraying, fluorocarbon coating, electrostatic powder coating, and electrolytic polishing. These treatments ensure superior corrosion resistance, aesthetic appeal, and durability.

Stock Supply and Fast Delivery:

In addition to custom-made products, we also offer common specifications in stock for urgent orders. This eliminates the need for additional processing time and cost, allowing you to use the products immediately.

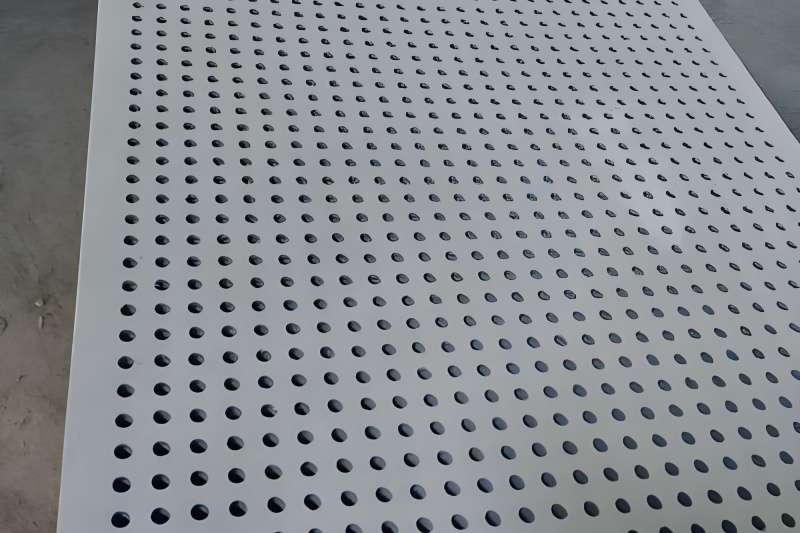

Specifications and Customization Options:

Sheet Size: Width less than 1.5 meters, length less than 4 meters, with other dimensions customizable.

Sheet Thickness: Available in thicknesses from 0.1mm to 20mm, with custom thickness options.

Hole Types: Available in a variety of shapes, such as round holes, oval holes, square holes, triangular holes, star-shaped holes, hexagonal holes, fish scale holes, and more.

Surface Treatment: Steel plates can be sprayed, fluorocarbon-coated, or electrostatically powder-coated; aluminum plates and stainless steel plates can also be treated with anodizing, fluorocarbon coating, and other options.

Pricing Information:

The price of muffled perforated plates depends on the specifications and models. We provide accurate quotes based on your specific requirements. Feel free to contact us via email with the specifications and models you need, and we will provide a detailed quotation.

Why Choose Us:

Custom Services: We offer customized muffled perforated plates tailored to your specific needs, ensuring the products perfectly fit your project requirements.

High-Quality Materials and Craftsmanship: We use premium materials and advanced processing techniques to ensure each muffled perforated plate provides exceptional noise control and long-lasting durability.

Global Cooperation: We are looking for global partners and welcome the opportunity to collaborate with you to expand our markets.

Contact Us:

If you're looking for effective, customized muffled perforated plate solutions, feel free to reach out to our professional team. Whether you need noise control solutions or further details about muffled perforated plates, we will offer the best advice and quotations to ensure the success of your project.