Features of Using Perforated Plates as Protective Screens

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 15:07:55 Browse:

With the growing demands for safety and aesthetics in industries, construction, and transportation, perforated plates have emerged as an innovative material for protective screens. Due to their unique design, excellent performance, and wide applicability, perforated plates are increasingly being used in various fields. This article explores the main features and advantages of perforated plate protective screens, helping you understand why perforated plates are the ideal solution for protective screens.

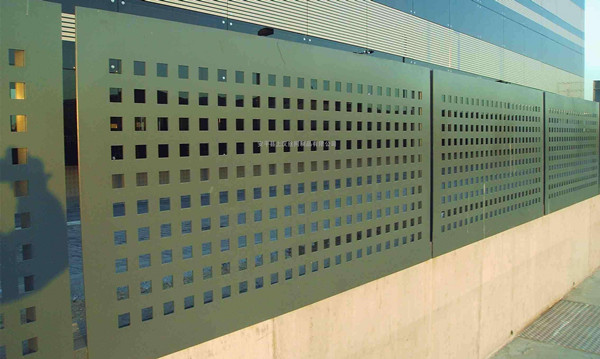

1. Innovative Design and Unique Appearance

Compared to traditional steel railings or protective screens, perforated plate guards offer a wide range of modern and stylish design choices. The types of perforations vary widely, including but not limited to round holes, oval holes, elongated circular holes, square holes, rectangular holes, triangular holes, pentagonal holes, hexagonal holes, octagonal holes, cross-shaped holes, plum blossom holes, diamond holes, fish scale holes, and louvered holes. These different hole shapes not only meet various functional requirements but also create a visually striking and distinctive appearance, enhancing the modern and artistic feel of a building or facility.

Whether used for building facades, isolation barriers, or industrial equipment protection, perforated plates blend seamlessly into their surroundings, providing functional protection while also being aesthetically pleasing. This unique design makes them an excellent choice in many architectural and decorative projects, especially where there is a need to balance both safety and aesthetics.

2. High-Efficiency Safety Protection

The structural design of perforated plate protective screens places a strong emphasis on safety, effectively resisting external impacts and interference. Perforated plates are usually made from a single metal sheet through a stamping process, eliminating the need for welding or assembly. This seamless connection makes the overall structure more stable, offering higher rigidity and strength. As a result, perforated plates can withstand significant pressure and impact, preventing loosening or deformation over time.

In addition, the perforation size can be precisely designed to meet specific needs, with smaller holes effectively blocking small animals (such as rats) and debris from entering, further enhancing the protective performance. This precise perforation design ensures higher safety, especially in areas that require protection from small animals or unauthorized access.

3. Excellent Corrosion Resistance and Durability

The corrosion resistance of perforated plates is another key advantage. Since perforated plates are generally made of high-quality metals (such as stainless steel or aluminum alloys), they are typically subjected to special surface treatments like spraying, powder coating, or hot-dip galvanizing. These treatments effectively prevent oxidation and corrosion, significantly extending the service life of the plates. Even in harsh environments, such as coastal or humid areas, perforated plates remain stable and aesthetically pleasing for long periods.

Additionally, perforated plate protective screens are available in a variety of colors. Powder coating provides a smooth surface and long-lasting color, further enhancing the visual appeal. This makes perforated plates not only functional but also a stylish addition to various building or decorative projects.

4. Good Ventilation and Transparency

The design of perforated plates offers excellent ventilation and transparency. In many situations where airflow is important, perforated plates effectively create an air passage, ensuring proper ventilation while still preventing the entry of external objects. This unique structure makes them ideal for environments where air circulation is required, yet safety must still be maintained, such as guardrails on high-rise buildings, isolation barriers, and more.

5. Strong Adaptability and Wide Applications

Perforated plate protective screens, with their flexible design and various processing methods, have a wide range of applications across different industries and fields. Whether used as decorative materials for building facades, protective screens for machines, traffic barriers, or industrial enclosures, perforated plates provide reliable safety and visual appeal. Moreover, perforated plates can be customized to fit specific hole sizes, shapes, and dimensions, offering high adaptability to meet the diverse needs of different industries and customers.

Conclusion

In summary, using perforated plates as protective screens not only provides superior structural safety and durability but also offers unique design, good ventilation, and broad applicability. Whether in the construction industry, transportation infrastructure, or industrial production, perforated plate protective screens offer significant advantages in both functionality and aesthetics. They are an ideal solution for modern safety protection systems.