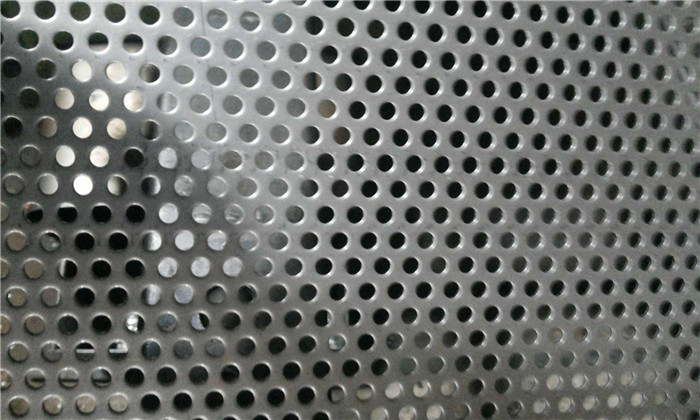

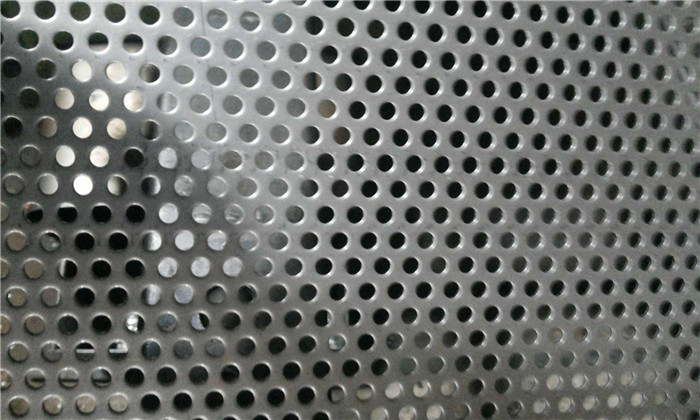

How to solve the problem of deformation of stainless steel perforated sheet in the production process

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 11:02:26 Browse:

Stainless steel Perforated sheet will experience some degree of bending and deformation after production, with the entire product taking on a bowed shape. This is caused by the deformation resulting from the stamping process during production, which is unavoidable. We can rectify this issue by using a straightening machine in the post-production process. After the straightening process, the flatness of Stainless steel Perforated sheet will be greatly improved.

We can also adjust the production process of Stainless steel Perforated sheet to reduce its flatness.

By improving the wear of the punch used in the production of Stainless steel Perforated sheet, we can regularly check the wear of the punch and replace it when it reaches a certain degree of wear.

When designing the mold for Stainless steel Perforated sheet, we can use CAD or other software to repeatedly calculate and adjust the gap between the upper and lower molds to achieve a reasonable mold gap, which will also affect the degree of deformation of Stainless steel Perforated sheet.

Stainless steel Perforated sheet