Key Features of Iron Plate Microporous Perforated Sheet

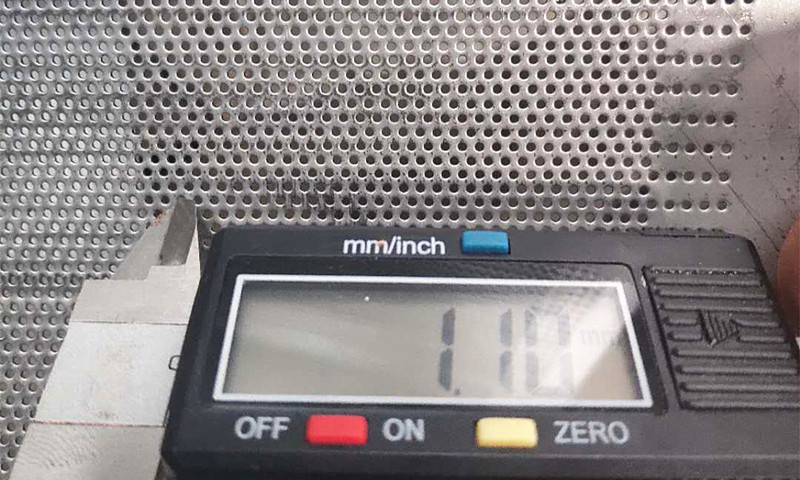

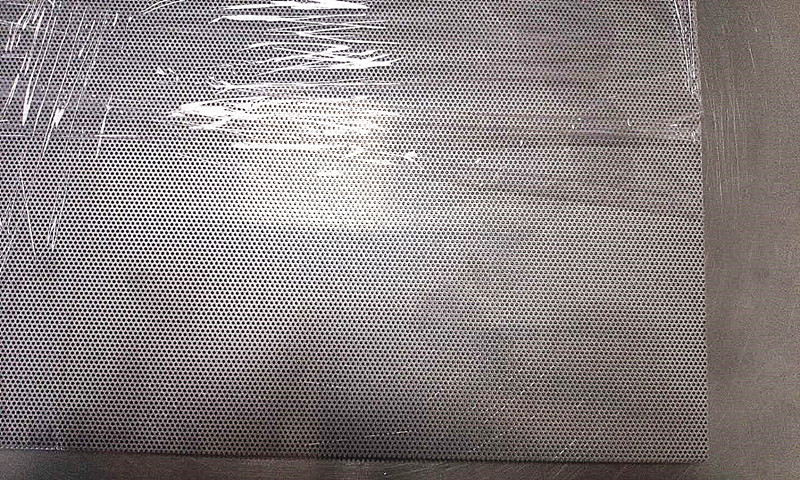

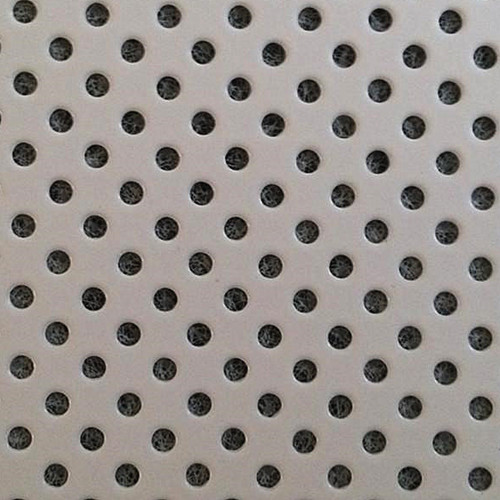

Precision Aperture: Iron plate microporous perforated sheets have very fine apertures, usually between 0.2mm and 3mm, making them ideal for industries requiring high precision in filtering and screening applications.

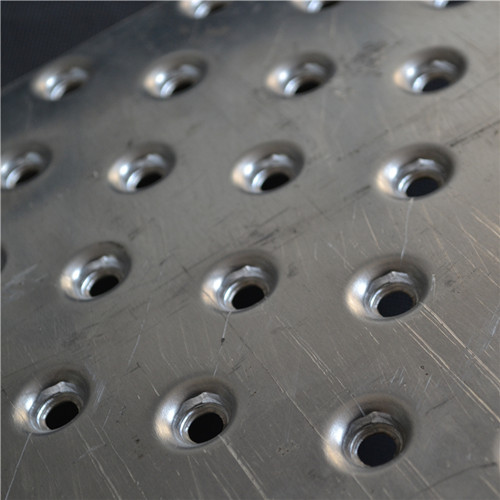

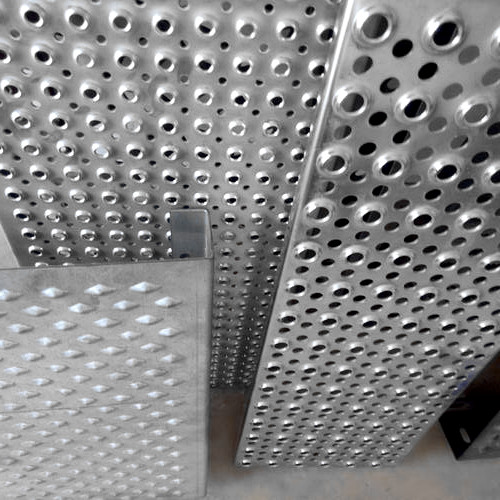

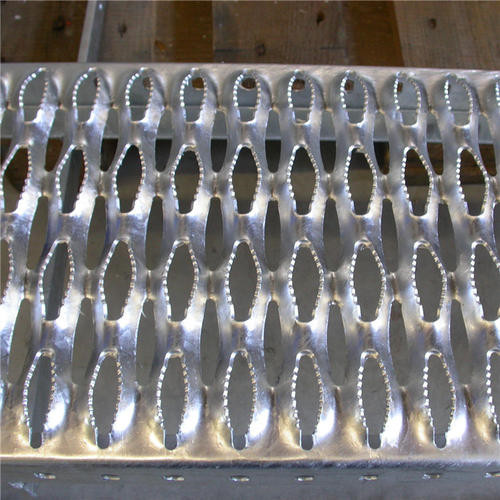

Diverse Hole Shapes: In addition to standard round holes, we offer other shapes, including oval holes, long round holes, hexagonal holes, etc. Custom shapes can also be provided according to specific customer requirements.

High-Strength Iron Plate Material: Our perforated sheets are made from high-quality iron plate, ensuring strength and durability for use in various harsh working environments.

Specifications and Customization Options for Iron Plate Microporous Perforated Sheet

Material: High-quality iron plate with excellent corrosion resistance, high temperature tolerance, and strength suitable for extreme conditions.

Thickness: The sheet thickness ranges from 0.1mm to 3mm, customizable based on customer requirements.

Size: Full customization is available, ensuring the sheets meet various engineering and application needs.

Aperture and Hole Shapes:

Aperture size: 0.2mm to 3mm (customizable)

Hole shapes: Round, oval, long round, hexagonal, and other custom shapes upon request.

Surface Treatment: We offer various surface treatments, including spraying, galvanizing, and nickel plating, to enhance the corrosion resistance and durability of the perforated sheets.

Applications of Iron Plate Microporous Perforated Sheet

Iron plate microporous perforated sheets have a wide range of applications, especially in industries that require precise filtering and high-strength materials. Here are some key application areas:

1. Filtration and Screening

Iron plate microporous perforated sheets are ideal for precision filtration of liquids and gases. They are widely used in the food and beverage industry, such as juice machine nets, soybean milk machine nets, and other food processing equipment. They are also used in pharmaceutical precision filters, filter plates, and cartridges to ensure that liquids or gases are free from impurities.

2. Petrochemical Industry

In the petrochemical industry, iron plate microporous perforated sheets are used as mud screens and filtration nets. They are capable of withstanding high temperatures and pressures, effectively screening out solid materials such as mud and sand. They are also used in chemical reaction containers, pipelines, and other equipment for protection and filtration.

3. Electrical Industry

The electrical industry has strict material requirements, and iron plate microporous perforated sheets are commonly used as metal leakage plates, cover plates, flat pins, lead frames, and other components. They provide excellent corrosion resistance and mechanical strength, ensuring long-term stable operation of electrical devices.

4. Precision Manufacturing and Decoration

In precision manufacturing, iron plate microporous perforated sheets are used for producing optical and mechanical parts, spring components, mobile phone accessories, and more. The precise hole shapes and excellent material properties make them ideal for manufacturing complex components.

5. Environmental Protection and Acoustic Soundproofing

Iron plate microporous perforated sheets are also widely used in environmental protection and acoustic soundproofing equipment. The fine apertures help absorb and filter sound waves, making them highly effective in noise control applications such as soundproof walls and shielding materials.

6. Chemical Fiber and Electroplating Industries

In the chemical fiber industry, these perforated sheets are commonly used as screening materials to filter and screen chemicals. In the electroplating industry, they are used as pickling meshes, offering resistance to corrosion during the plating process and extending service life.