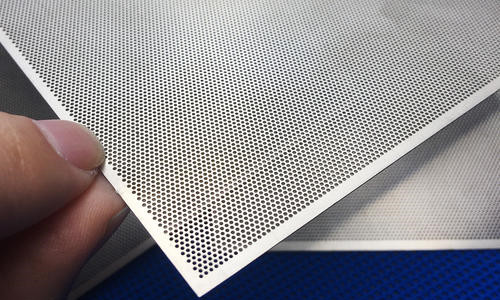

Specifications and Customization

We offer a variety of specifications and customization options for stainless steel microporous perforated sheets to meet the needs of different industries and projects. Below are the main specifications and customization options:

Materials

We use high-quality stainless steel materials, mainly including the following types:

201 Stainless Steel: Provides good corrosion resistance and is widely used in general environments.

304 Stainless Steel: Commonly used in many applications, offering high corrosion resistance and excellent machinability.

316 Stainless Steel: Offers superior corrosion resistance, particularly in chemical, pharmaceutical, and marine environments.

316L Stainless Steel: A low-carbon version of 316 stainless steel, ideal for high-quality welding applications.

Size

Our stainless steel microporous perforated sheets can be customized according to customer requirements. Common sizes include:

1000mm x 2000mm

1220mm x 2440mm Sizes can also be customized according to project requirements to meet specific design needs.

Thickness

The thickness of stainless steel microporous perforated sheets can be customized based on the aperture size and usage needs. Common thicknesses include:

0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm, etc. Non-standard thicknesses are also available to ensure the best performance for specific applications.

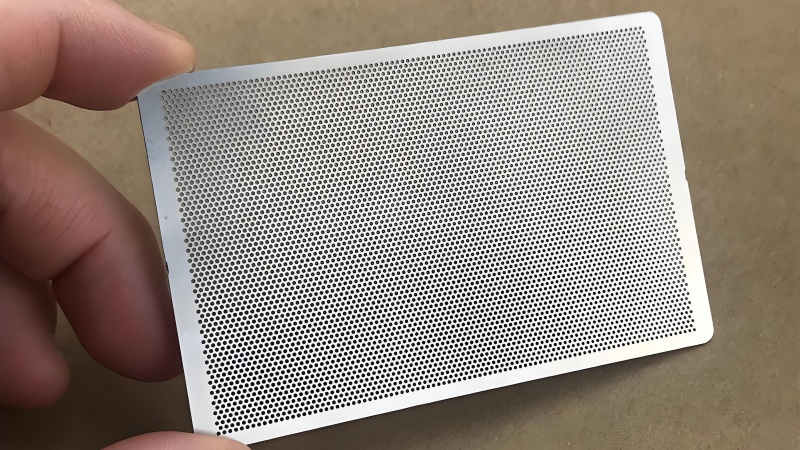

Aperture

The aperture size of stainless steel microporous perforated sheets can be customized based on requirements. Common aperture sizes include:

0.6mm, 0.8mm, 1.0mm, 1.5mm, 2.0mm Special apertures can be manufactured according to customer specifications to meet specific filtration or airflow needs.

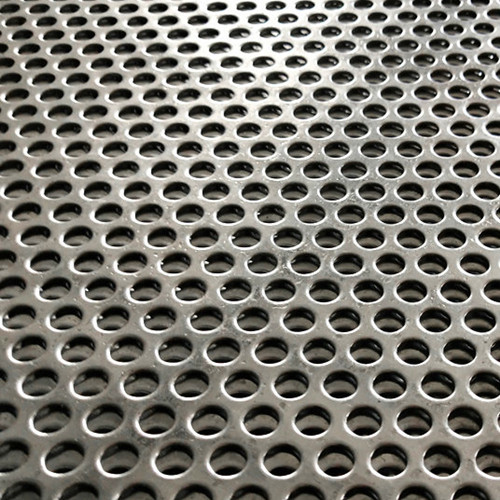

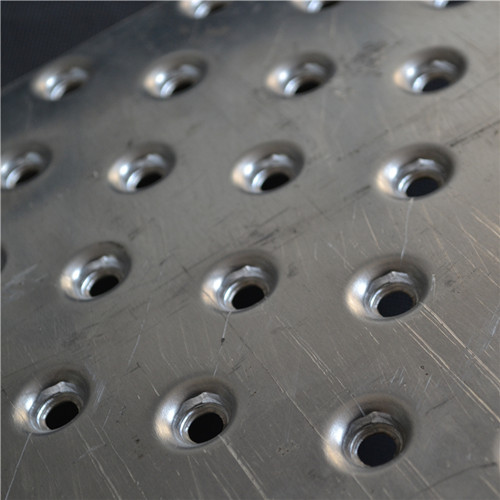

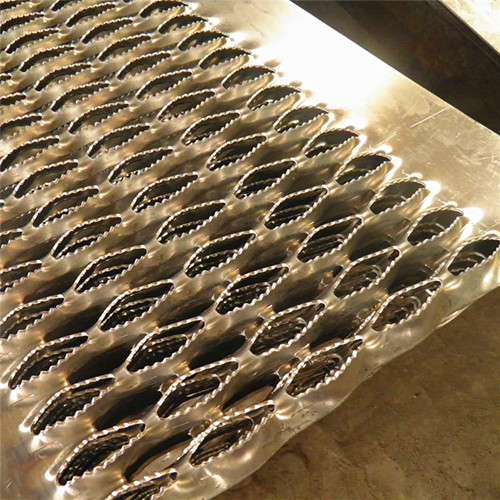

Hole Types

We offer a variety of hole types, including:

Round holes: The most common type, suitable for most applications.

Long round holes: Used in applications that require larger airflow or ventilation.

Square holes: Ideal for applications requiring high load-bearing capacity.

Rectangular holes: Customizable for specific design requirements.

Special hole types: We can also produce custom hole types based on customer needs.

Hole Spacing

Hole spacing refers to the distance between the centers of adjacent holes or the distance from the edge of one hole to the edge of the neighboring hole. Generally, the spacing between holes is smaller than the thickness of the sheet. We offer customized hole spacing options to meet various application requirements.

Product Advantages

Stainless steel microporous perforated sheets offer a variety of advantages that make them indispensable in many industries. Key benefits include:

Exceptional Corrosion Resistance: Made from high-quality stainless steel materials, these perforated sheets are highly resistant to corrosion, making them ideal for harsh environments such as chemical plants, wastewater treatment, and marine applications.

Excellent Breathability and Filtration Performance: The microporous design offers excellent airflow and filtration capabilities, making them ideal for air purification and filtration systems.

Customization Services: We provide flexible customization options, allowing customers to choose from a variety of aperture sizes, hole types, thicknesses, and dimensions to suit their specific needs.

High Load-Bearing Capacity and Slip Resistance: Our perforated sheets are not only capable of bearing high loads but also offer excellent slip resistance, ensuring safety in harsh industrial environments.

Environmental and Safety Standards: We strictly adhere to international environmental standards in the manufacturing process, ensuring that our products are free from harmful substances and safe for use in sensitive industries such as food, medical, and environmental protection.

Applications

Stainless steel microporous perforated sheets, with their outstanding performance, are widely used in the following industries:

Ventilation and Air Filtration Systems: Used in industrial ventilation systems, air conditioning systems, and air filtration devices to ensure stable operation and improved air quality.

Environmental Protection Facilities: Commonly used in wastewater treatment, gas purification, and other environmental applications, effectively filtering pollutants and improving environmental outcomes.

Industrial Equipment Protection: Used as protective screens, barriers, or enclosures for industrial equipment, preventing dust and debris from entering, thus ensuring the long-term stable operation of machinery.

Architectural Decoration and Aesthetic Design: Used in building facades and interior decoration, stainless steel microporous perforated sheets offer both aesthetic appeal and durability, becoming an essential element in modern architectural design.

Safety Grills and Protective Screens: Due to their robust structure and slip-resistant properties, these perforated sheets are widely used in industrial safety applications to prevent accidents and ensure worker safety.