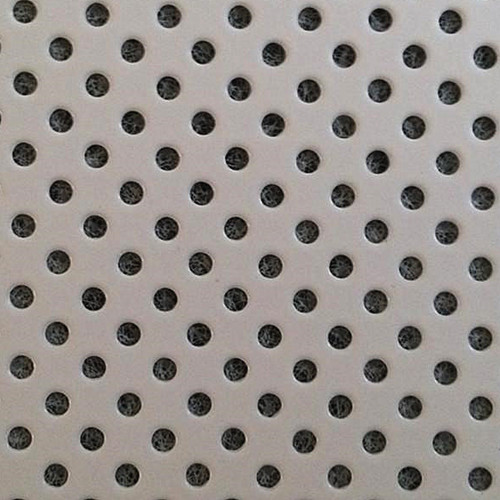

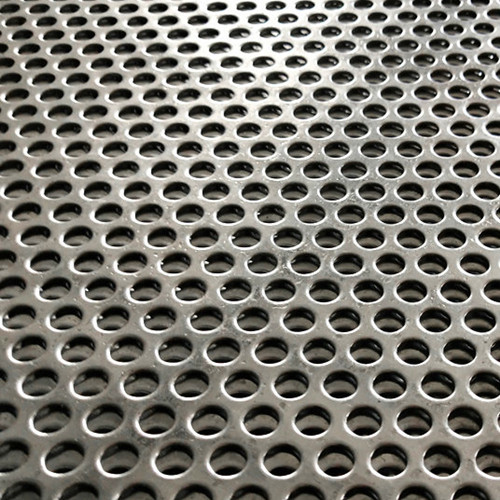

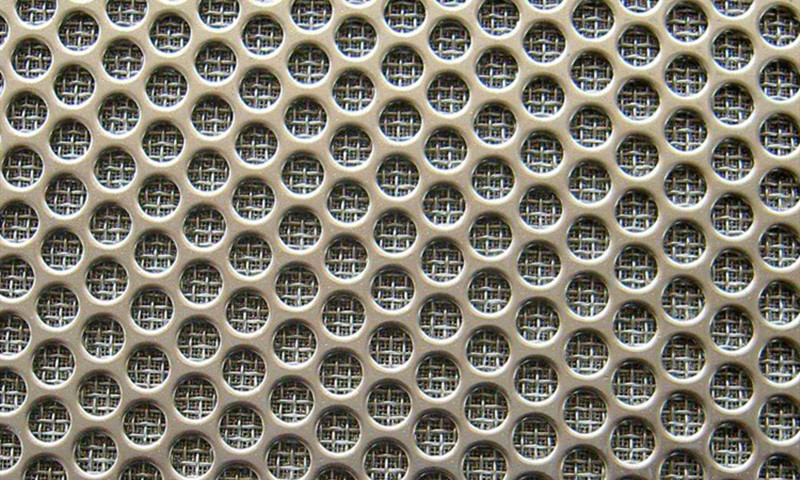

The 3003 aluminum perforated sheet is a mesh product made from high-quality 3003 aluminum alloy, processed by CNC punching machines. It is widely used in various fields, including construction, decoration, industrial filtration, and ventilation. Compared to suppliers from other countries, our products stand out by offering customized solutions, including different sizes, materials, thicknesses, hole shapes, and hole diameters, to meet the diverse needs of our customers.

Customization Options:

Sheet Width: Our 3003 aluminum perforated sheets can be customized according to customer requirements, with a width range from 50mm to 2000mm.

Sheet Length: The length of the 3003 aluminum perforated sheets can be customized according to requirements, with a length range from 50mm to 6000mm. For coils, the length can range from 6 meters to 300 meters.

Sheet Thickness: We offer thickness options from 0.3mm to 20mm, which can be customized based on customer needs.

Material of the Sheet: The perforated sheet is made from high-quality 3003 aluminum alloy, which has excellent corrosion resistance and oxidation resistance. The main components include:

Manganese (Mn): 1.0% to 1.5%

Copper (Cu): 0.05% to 0.2%

Iron (Fe): ≤0.7%

Silicon (Si): ≤0.6%

Zinc (Zn): ≤0.1%

Aluminum (Al): Remainder

Density: approximately 2750kg/m³

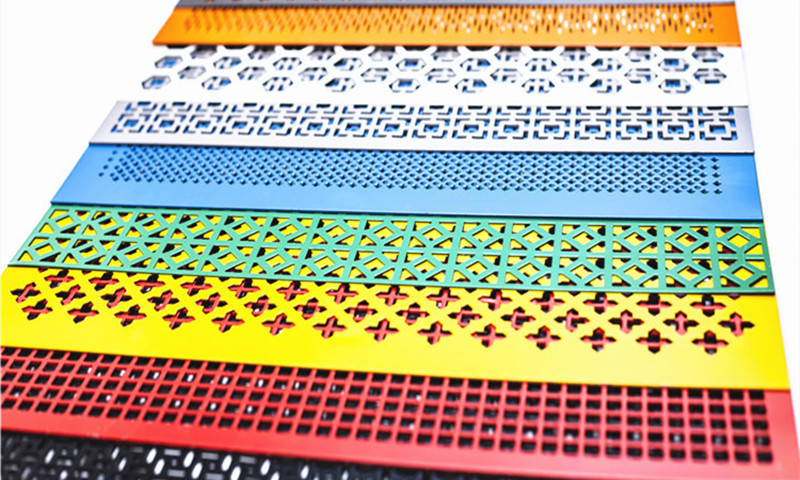

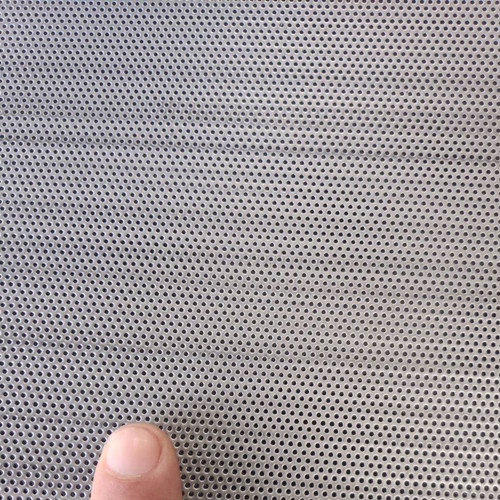

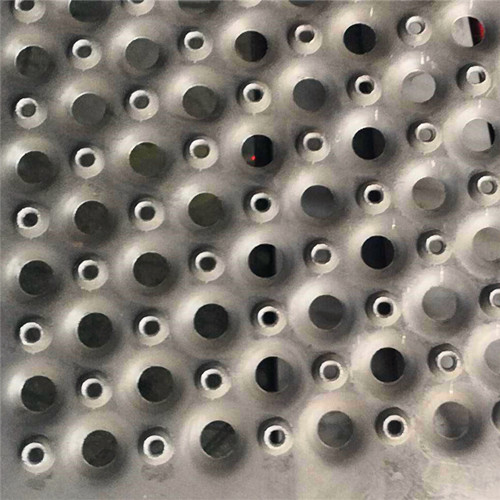

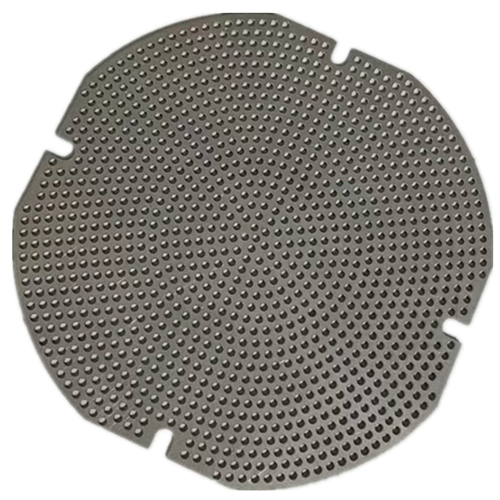

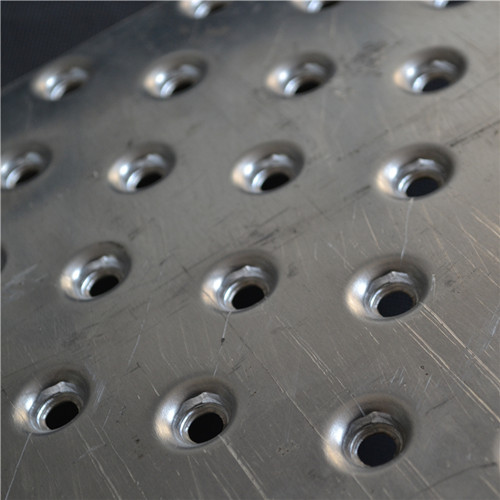

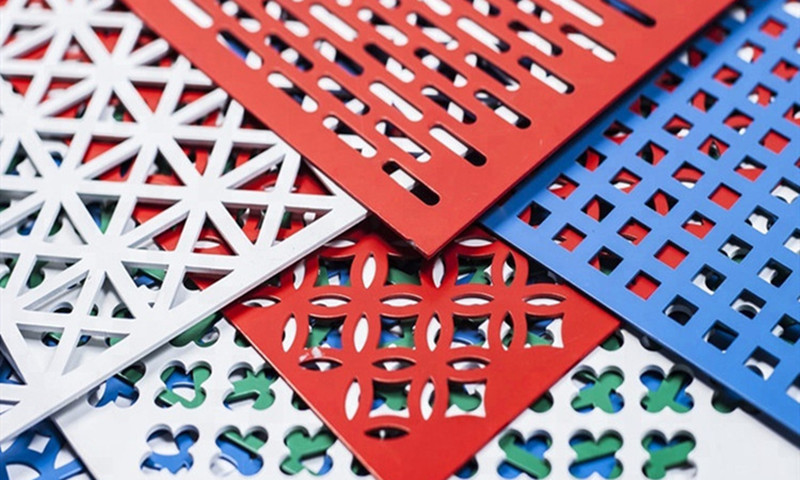

Hole Shape Options: The 3003 aluminum perforated sheet offers various standard and customized hole shapes, including:

Round holes, oval holes, rectangular holes, square holes, triangular holes, star-shaped holes, hexagonal holes, 8-shaped holes, cross-shaped holes, slanted holes, I-shaped holes, diamond holes, fish-scale holes, nail holes, bridge holes, louver holes, round drum holes, crocodile-mouth holes, and other special hole shapes. We can also provide customized hole shapes based on customer drawings.

Hole Diameter and Pitch: The hole diameter of the 3003 aluminum perforated sheet can be customized, ranging from 1mm to 300mm. Common hole sizes can be processed using standard molds. The pitch between holes is usually more than 1.5 times the thickness of the sheet, and specific pitches can be customized according to customer needs.

Deep Processing Services: To meet higher processing requirements, the 3003 aluminum perforated sheet can undergo various deep processing treatments, including but not limited to:

Bending and Rolling: Precision bending and rolling processing according to product requirements.

Cutting and Laser Cutting: Precise cutting to ensure high-quality processing results.

Electrostatic Spraying and Anodizing: Enhance the corrosion resistance and appearance of the aluminum sheet, extending the product’s lifespan.

Advantages:

Personalized Customization: We provide tailor-made services based on customer needs, from hole shape to size, reducing the need for secondary processing.

High-Quality Materials: Made from high-quality 3003 aluminum alloy, ensuring the strength, durability, and corrosion resistance of the perforated sheet.

Global Supply: We offer customized solutions for global customers, helping you easily meet the requirements of various applications. Whether it's for architectural decoration, industrial applications, or daily ventilation and aesthetic needs, the 3003 aluminum perforated sheet provides efficient and reliable solutions.

.

.