Deformation and Flattening Treatment of Metal Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-06 10:27:23 Browse:

In the production process of metal perforated sheets, CNC punching machines are typically used for continuous punching operations. However, this process often leads to deformation and warping of the metal sheets. The main reasons for these issues are as follows:

Deformation During Punching Process

The production of metal perforated sheets involves applying pressure from above through a punch die, which can cause slight deformation of the metal sheet. Additionally, a large amount of heat is generated in the punching area, and the thermal expansion and contraction effects further exacerbate the deformation. Therefore, the smaller the hole spacing and the thinner the sheet, the more pronounced the degree of deformation.

Influence of Steel Hardness on Deformation

The material hardness used in the production of metal perforated sheets also affects the degree of deformation. The higher the hardness of the metal sheet, the greater the deformation produced during the punching process. This is an unavoidable phenomenon, but certain technical measures can be taken to reduce deformation.

Technical Measures to Reduce Deformation

To minimize the deformation of metal perforated sheets as much as possible, the following technical measures can be adopted:

Use sharp punches: Sharp punches can reduce friction and compression, thereby lowering the risk of deformation.

Regularly check the wear condition of the punches: Worn punches increase pressure, leading to more deformation, so it is necessary to regularly check and replace the punches.

Regularly adjust the mold clearance: Uneven mold clearance can lead to irregular deformation, so regular inspection and adjustment of the mold clearance are crucial.

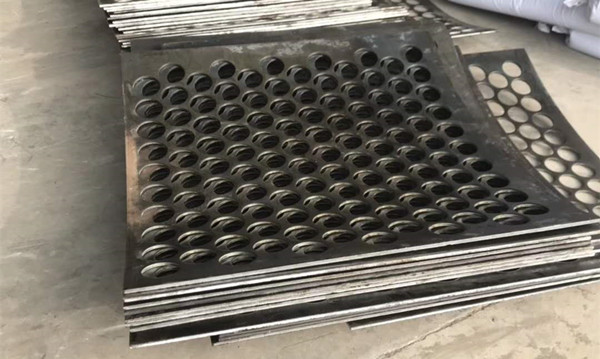

Unleveled metal perforated sheet

Methods for Flattening Metal Perforated Sheets

After deformation occurs, metal perforated sheets can be flattened using various equipment. Common flattening methods include:

Multi-roll leveling machine: This is a commonly used method for leveling metal perforated sheets. By adjusting the machine settings and passing the sheet through the rollers, deformation can be significantly reduced. For sheets requiring higher flatness, multiple passes through the machine can further improve flatness.

Hydraulic leveling machine: For very thin sheets or perforated sheets with small hole spacing, the hydraulic leveling machine is a more precise choice. It can level the perforated sheet to almost its pre-punching state, achieving extremely high flatness.

By using these leveling methods, the deformation of metal perforated sheets can be effectively reduced, ensuring the flatness and stability of the final product.

Metal Perforated Sheet Leveling Machine

Conclusion

Deformation of metal perforated sheets is a common production issue, but it can be effectively reduced through appropriate technical measures and proper leveling treatment, ensuring product quality. Understanding the causes of deformation during the punching process, the impact of hardness on deformation, and adopting suitable leveling methods are crucial for improving the production efficiency of metal perforated sheets and the quality of the final product.

During the production process, the quality and stability of metal perforated sheets directly affect the subsequent usage effect. Therefore, by continuously optimizing the production process and selecting high-quality equipment and materials, the quality of each batch of perforated sheets can be effectively ensured to meet standard requirements.

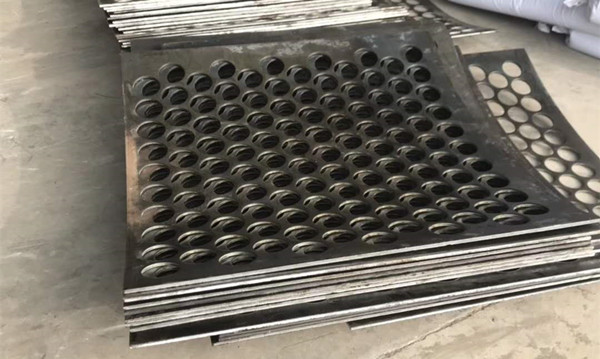

Perforated sheet after leveling