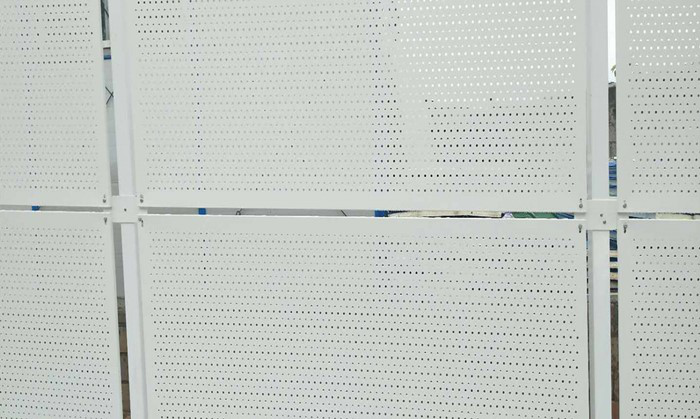

Perforated metal panels are prized for their breathability, strength, and visual appeal, making them ideal for façades, partitions, and ceilings. Choosing the right fixing methods not only guarantees structural stability but also preserves the panel’s corrosion-resistant finish. The two most common approaches are screw (or bolt) fixing and welding fixing, each with distinct advantages. Selecting the appropriate method depends on project requirements and environmental conditions.

I. Screw Fixing Methods

1. Direct Screw Installation

Procedure: Use self-tapping screws to fasten the panel directly into the substrate (e.g., wood or metal framing).

Advantages: Quick and easy installation without pre-drilling.

Tip: Verify that the substrate thickness can withstand the screw torque to prevent panel distortion.

2. Pre-drilled Hole Alignment

Procedure: If the panel edge already has factory-punched holes, align these with the framing and secure using standard screws or rivets.

Advantages: Protects the factory finish and extends corrosion resistance.

Best for: Outdoor or high-humidity environments where coating integrity is paramount.