Professional Microporous Stainless Steel Perforated Sheet Manufacturer – Global Supply from China

Product Overview

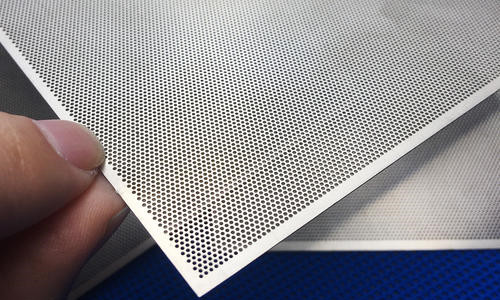

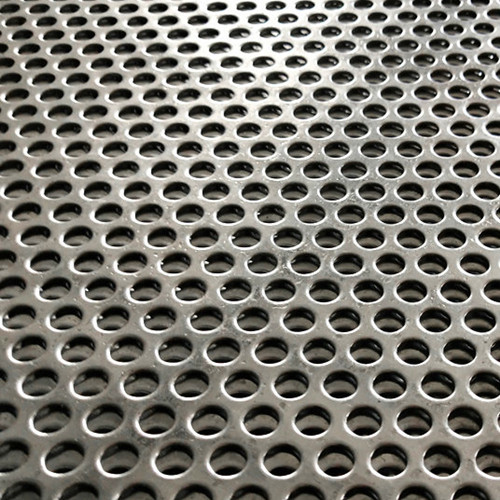

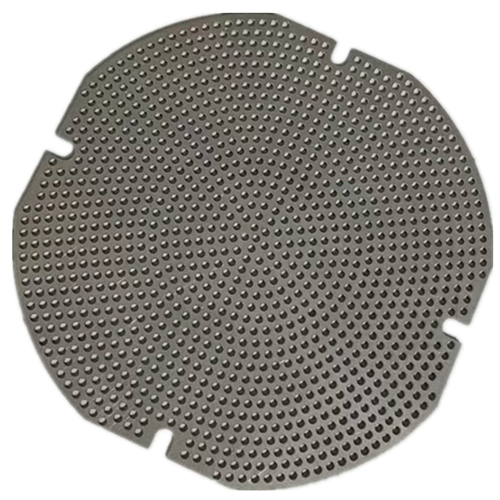

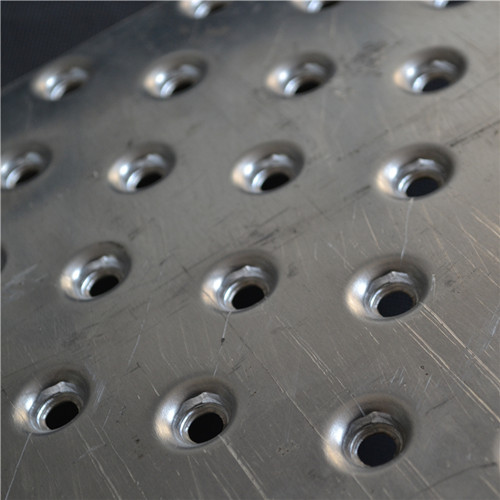

Our Microporous Stainless Steel Perforated Sheet is a high-precision filtering material crafted from premium stainless steel using CNC punching technology. With uniform hole patterns (typically <2mm diameter) and exceptional durability, it’s ideal for industrial sieving, architectural cladding, and eco-friendly equipment requiring (precision filtration).

Key Features

Material Options: 304, 316, 316L stainless steel (ASTM-compliant).

Precision Holes: Standard apertures 0.6–2.0mm (customizable from 0.2mm), ±0.05mm spacing tolerance.

Thickness Range: 0.1–2.0mm for varying load-bearing needs.

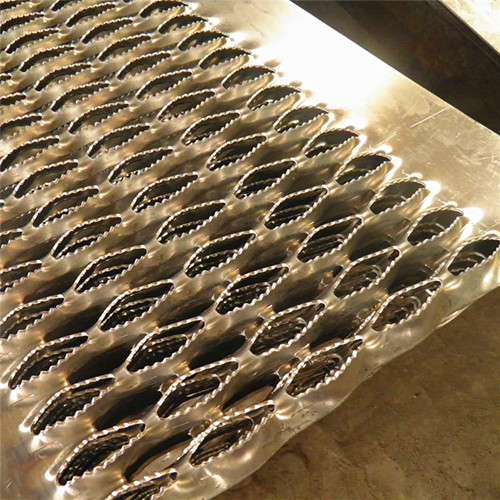

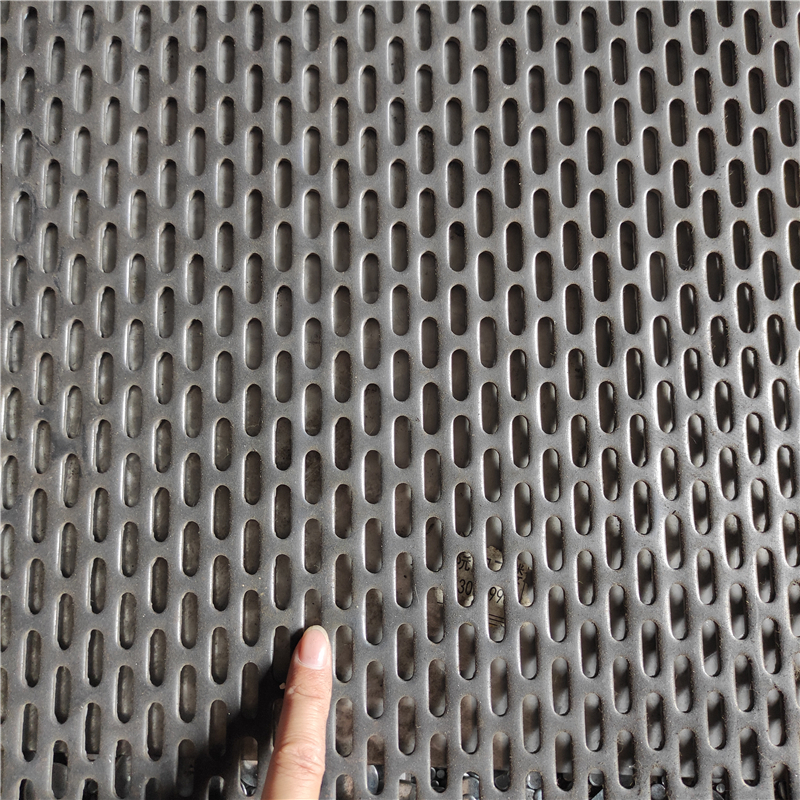

Hole Patterns: Standard round/square holes + custom shapes (fish-eye, hexagonal, etc.).

Surface Finishes: Mirror polish, brushed, sandblasted, or other treatments upon request.

Technical Specifications

Standard Sizes:

Sheets: 1000×2000mm, 1250×2500mm (max. width 3000mm for custom orders).

Temperature resistance: -20°C to 650°C (varies by material).

Customization Capabilities:

Non-standard hole sizes (must meet aperture ≥ thickness rule).

Unique layouts (staggered, linear, etc.).

Hybrid designs (e.g., perforated + embossed patterns).

Applications

1.Industrial Filtration:

Catalyst screening in petrochemical plants.

Powder grading for pharmaceuticals.

Food processing vibratory sieves.

2.Architecture & Design:

Ventilated facade panels.

Acoustic ceiling systems.

Artistic structural elements.

3.Environmental Solutions:

Wastewater aeration panels.

Air purifier filter layers.

Dust collector components.

4.Electronics & Hardware:

EMI shielding for enclosures.

Protective grilles for sensors.

Vibration-damping bases.

Production Process

1.Material Inspection: Spectrometer-verified steel.

2.CNC Punching: 800㎡ daily output per machine.

3.Deburring: Mechanical/electrolytic polishing.

4.Quality Control: 100% dimensional checks via optical projectors.

Quality Assurance

Raw material hardness/corrosion resistance tests.

Hourly sampling for hole consistency during production.

Global Services

Trade terms: EXW, FOB, CIF.

Technical support: DWG/DXF file compatibility.

Fast turnaround: Prototypes in 7 days (rush service available).

Lead time: 7–35 days (complexity-dependent).

FAQ

Q: What’s the smallest achievable hole size?

A: 0.2mm is technically possible if hole size ≥ sheet thickness.

Q: How are oversized sheets shipped?

A: Special crates secure sheets exceeding 2500mm.

Request a Quote

Provide these details for accurate pricing:

Material grade (e.g., 304/316).

Sheet thickness (mm).

Hole size/pattern sketch.

Surface finish preferences.

Certifications needed (e.g., ROHS).

Email: 342096438@qq.com

(Subject line: “Microporous Sheet Quote” for priority response.)