As a manufacturer of Perforated Steel Sheet from China, we specialize in providing customized Perforated Steel Sheet solutions for clients worldwide. With years of industry experience, advanced manufacturing technology, and a global service network, we have become a trusted supplier across various industries. Our Perforated Steel Sheets are widely used in construction, industrial, decorative, and transportation fields, meeting clients' needs for functionality, durability, and aesthetic appeal. Our goal is to earn the trust of global partners through high-quality products and professional services, driving the growth of international business.

Custom Services: Meeting the Unique Needs of Global Clients

Our Perforated Steel Sheet customization services are designed to provide tailored solutions for each client. Whether for large construction projects or industrial applications, we ensure the best-fit products for your specific needs. Here are the main customization options we offer:

Custom Hole Sizes and Shapes:

1.We offer a variety of hole shapes such as round holes, square holes, cross holes, fish-scale holes, and more, which can be designed based on client requirements.

2.Hole sizes range from 3mm to 30mm, ensuring functionality for various applications, such as filtration, ventilation, and decoration.

3.Hole spacing and layout can be customized according to project specifications to achieve optimal performance.

Material Options:

2.Each material has unique advantages: galvanized steel offers good corrosion resistance, stainless steel is ideal for high-strength and weather-resistant environments, and aluminum is lightweight with excellent processing properties.

Plate Thickness and Dimensions:

1.We offer a range of plate thicknesses from 0.3mm to 8mm, catering to different strength and durability requirements.

2.Standard sizes include 1000mm x 2000mm, 1200mm x 2400mm, 1250mm x 2500mm, 1500mm x 3000mm, though custom dimensions can be provided based on client needs.

3.We also offer custom roll options for large orders, which is especially convenient for large-scale projects or bulk requirements.

Surface Treatment:

1.We provide various surface treatment options such as spray painting, powder coating, electroplating, and more, to enhance the corrosion resistance and aesthetic appeal of the steel plates.

2.Stainless steel and aluminum plates can undergo polishing treatment, ensuring a smooth surface with high gloss.

Specifications of Perforated Steel Sheets

We offer a wide range of standard and customized specifications for Perforated Steel Sheets to meet different customer requirements:

Materials: Galvanized steel, stainless steel (304, 316, 201), aluminum, etc.

Plate Thickness: Common thicknesses range from 0.3mm to 8mm, with special requests for thicker or thinner plates.

Hole Shapes and Sizes: Common hole shapes include round holes, cross holes, fish-scale holes, etc., with hole sizes ranging from 3mm to 30mm. Hole spacing and layout can be customized as per requirements.

Dimensions: Standard sizes include 1000mm x 2000mm, 1200mm x 2400mm, 1250mm x 2500mm, 1500mm x 3000mm, with custom sizes available upon request.

Surface Treatment: Various treatment options such as spray painting, powder coating, galvanizing, electroplating, etc., for enhanced durability and corrosion resistance.

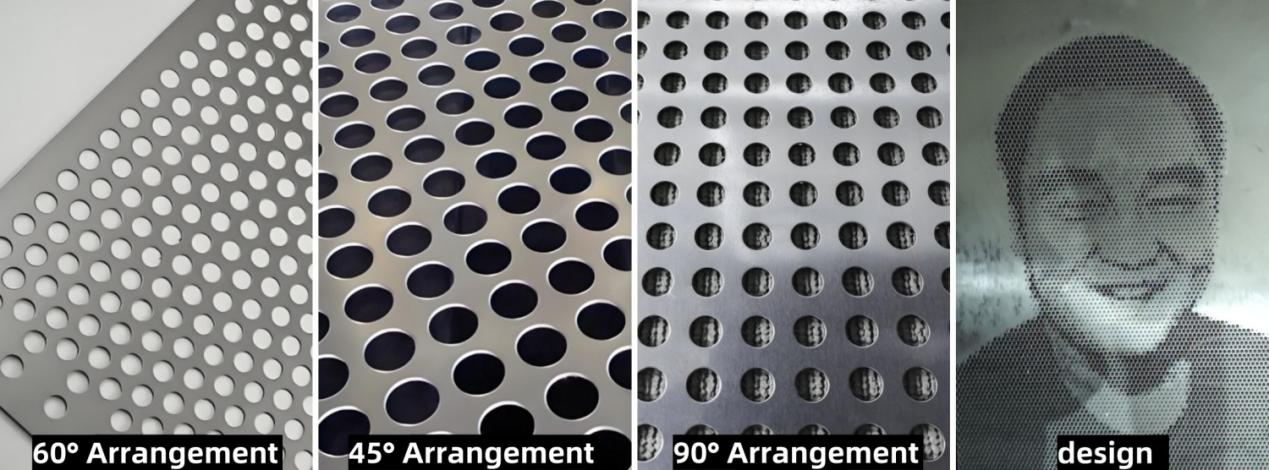

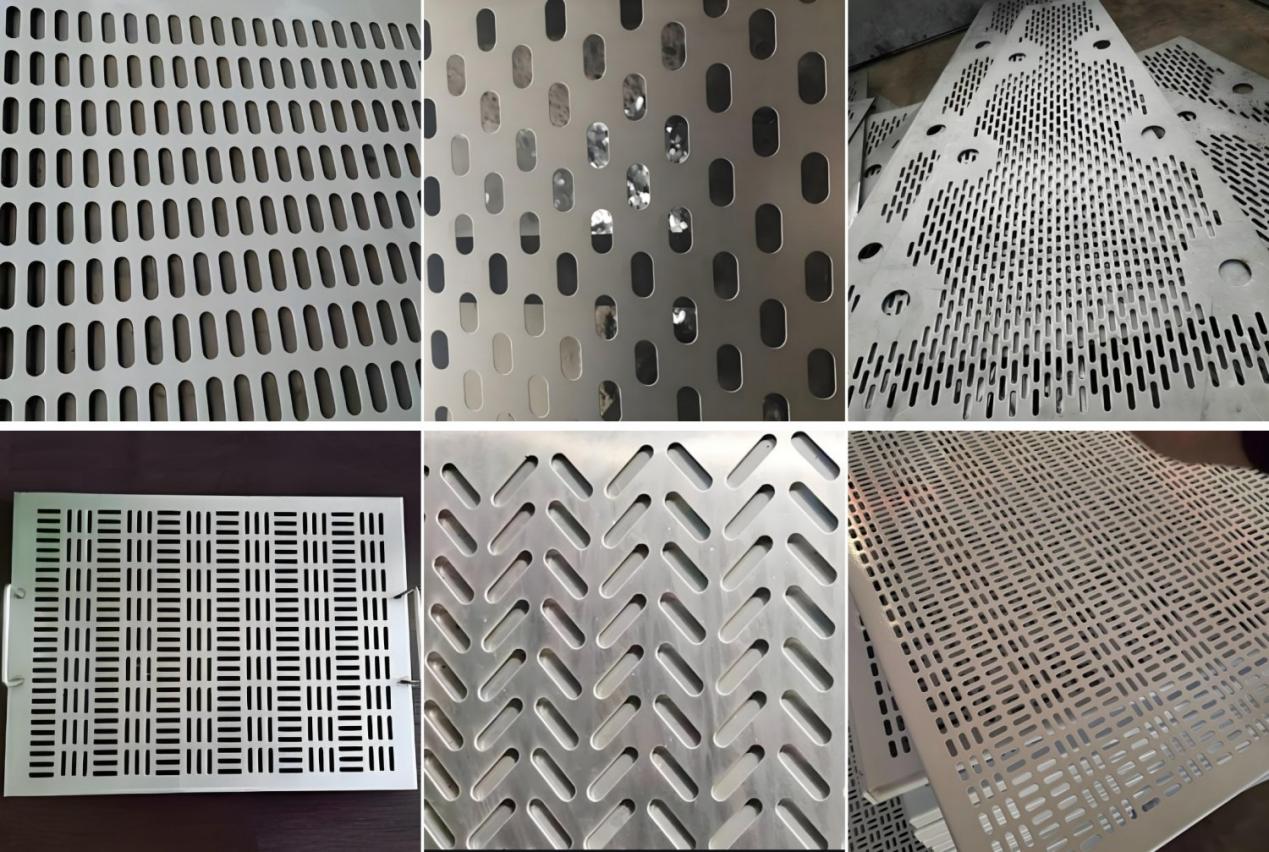

Perforated Steel Sheet Hole Pattern Display

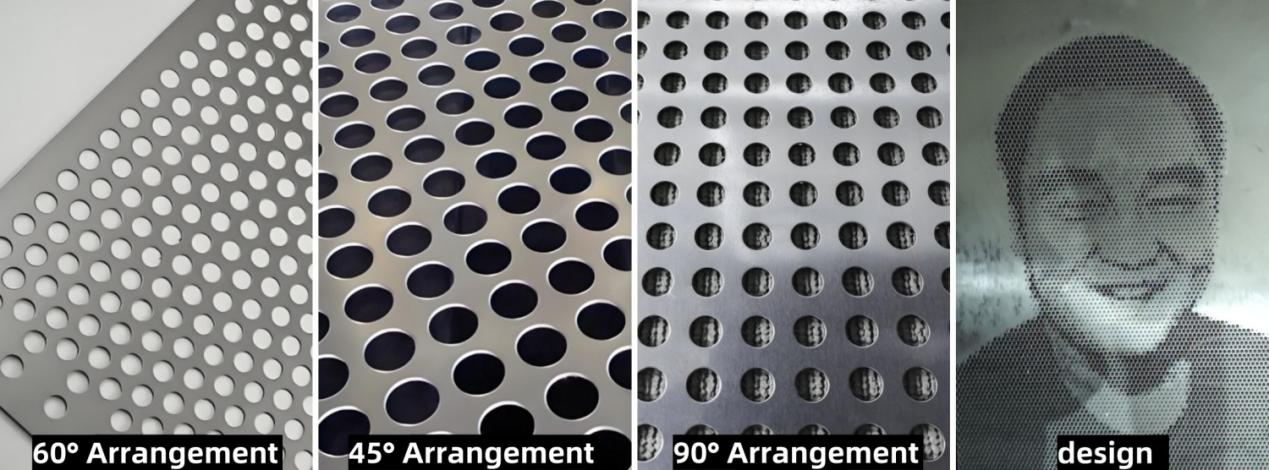

Round Hole

Round Hole Perforated Steel Sheet

The standard arrangement for round hole perforated steel sheets is a 60° pattern. The 45° and 90° patterns are relatively less common. Irregular patterns can be produced based on the hole size and different combinations, creating product designs that are often used in decorative applications.

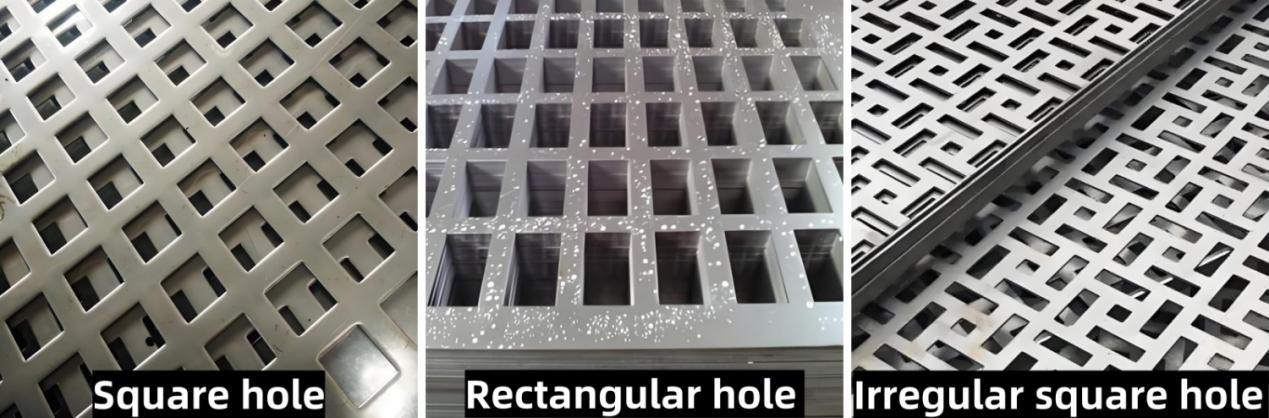

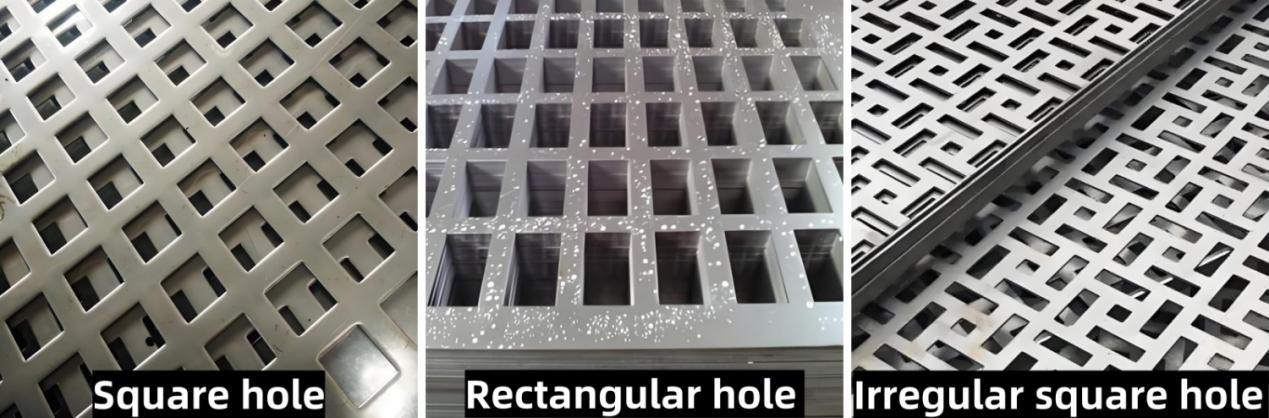

Square Hole

Square Hole perforated steel sheet

Square hole perforated steel sheets are commonly used in decorative applications or mechanical protective covers. Typically, the hole size, mesh spacing, and arrangement are customized based on customer requirements, and this type of perforated steel sheet is generally not available in stock.

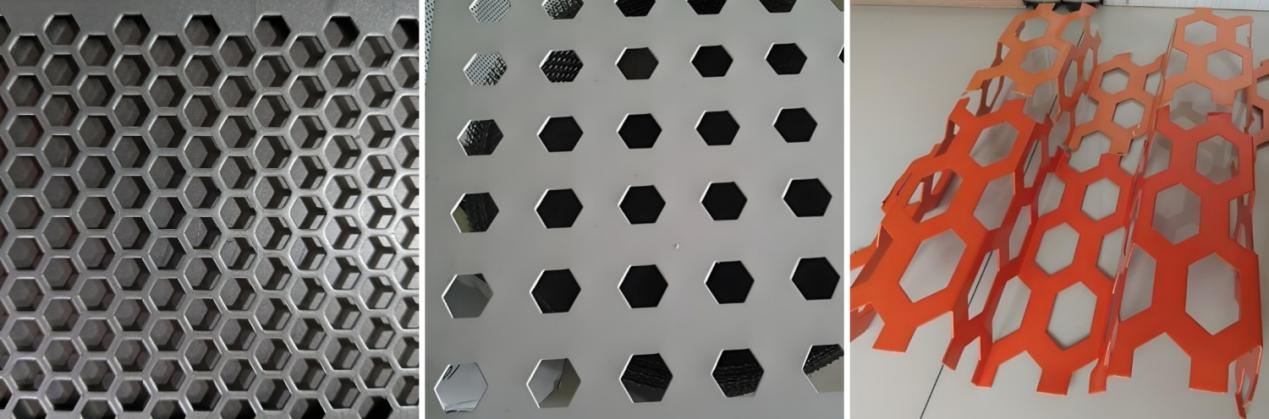

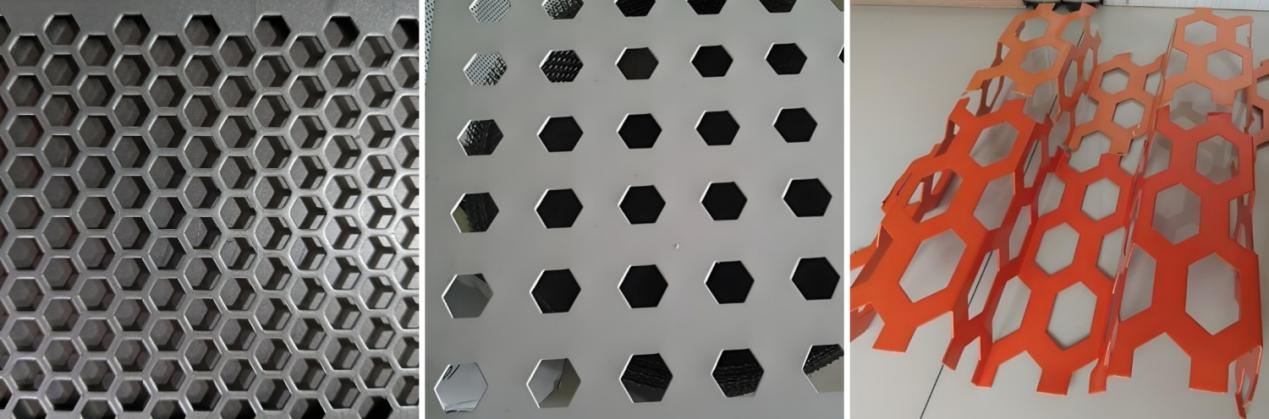

Hexagonal Hole

Hexagonal Hole perforated steel sheet

Hexagonal hole perforated steel sheets are commonly used in applications that require a larger open area and high airflow, such as ventilation grilles, filtration equipment, and more. Additionally, the hexagonal holes are typically arranged in a standard 60° pattern, providing higher structural strength and aesthetic appeal. This type of perforated steel sheet is often used in both industrial and decorative applications, and is usually custom-manufactured according to customer specifications.

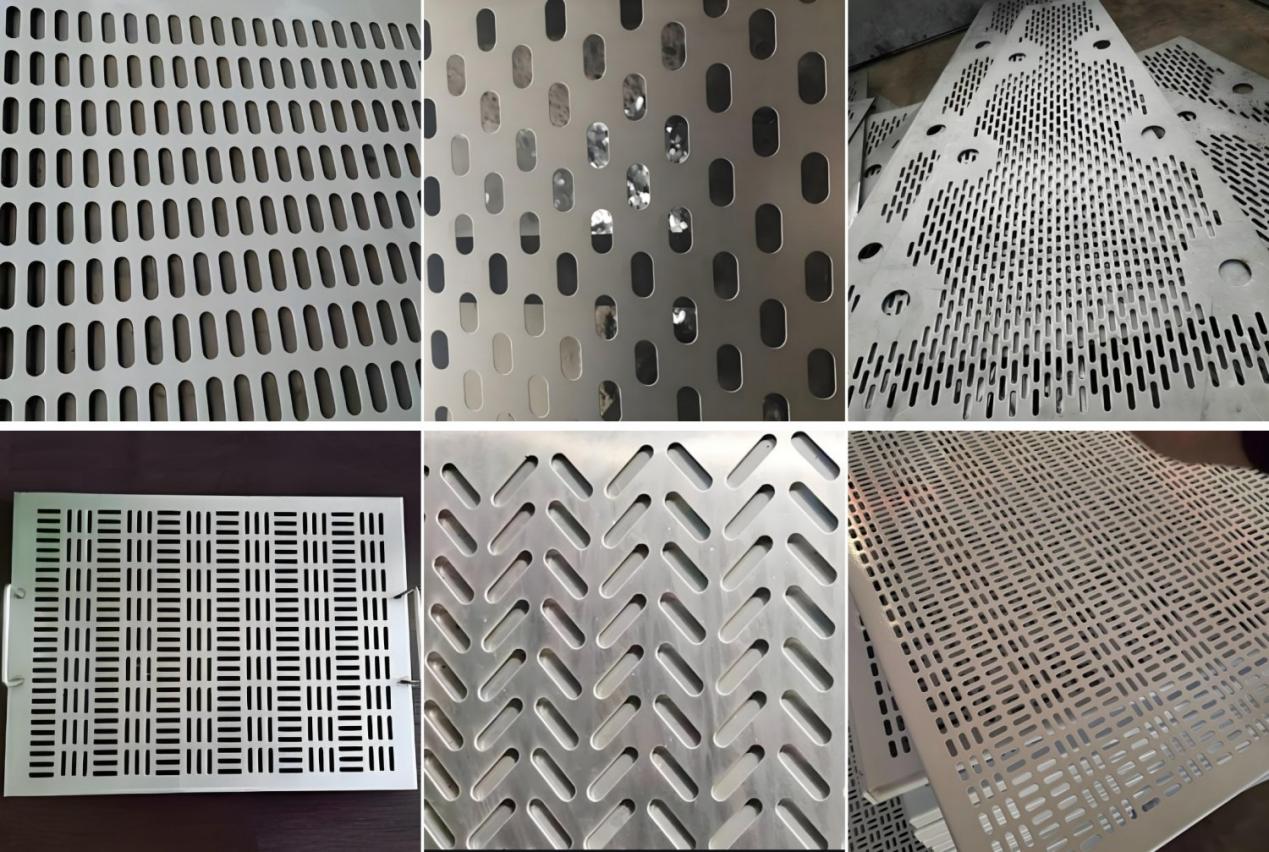

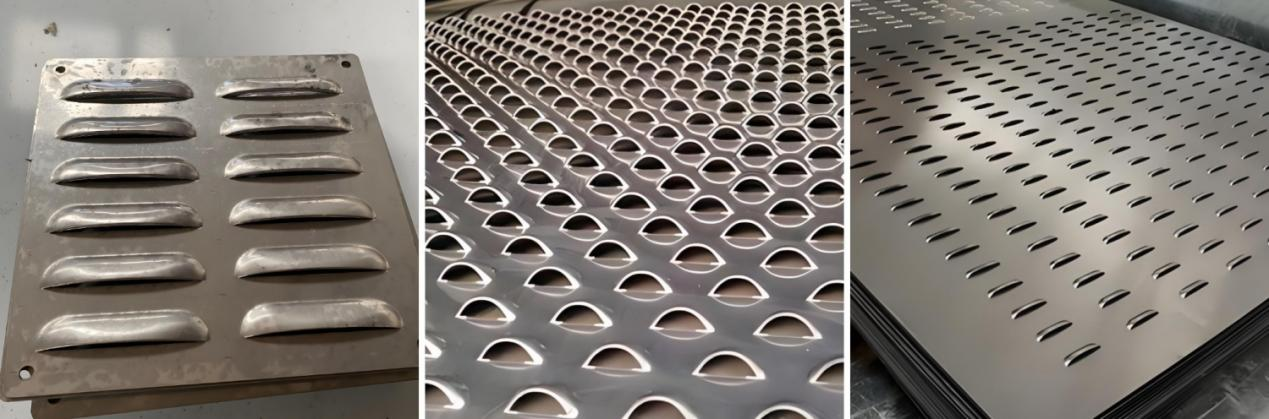

Slot Hole

Slot Hole perforated steel sheet

Slot perforated steel sheets are commonly used in applications that require a larger open area, offering higher airflow and filtration performance. The arrangement of the slot holes can be customized according to customer requirements. Common applications include air filters, ventilation systems, and various mechanical protective covers. Due to their unique shape, slot perforated steel sheets are also widely used in fields with high decorative and functional requirements.

Cross Hole

Cross hole perforated steel sheet

Cross hole perforated steel sheets are typically used in applications that require high strength and good airflow. The holes are arranged in a cross pattern, providing excellent load-bearing capacity and an attractive visual effect. Cross hole perforated steel sheets are widely used in ventilation systems, filtration equipment, as well as decorative walls and screens. Due to their unique arrangement, cross hole perforated steel sheets are usually custom-manufactured according to the specific requirements of customers.

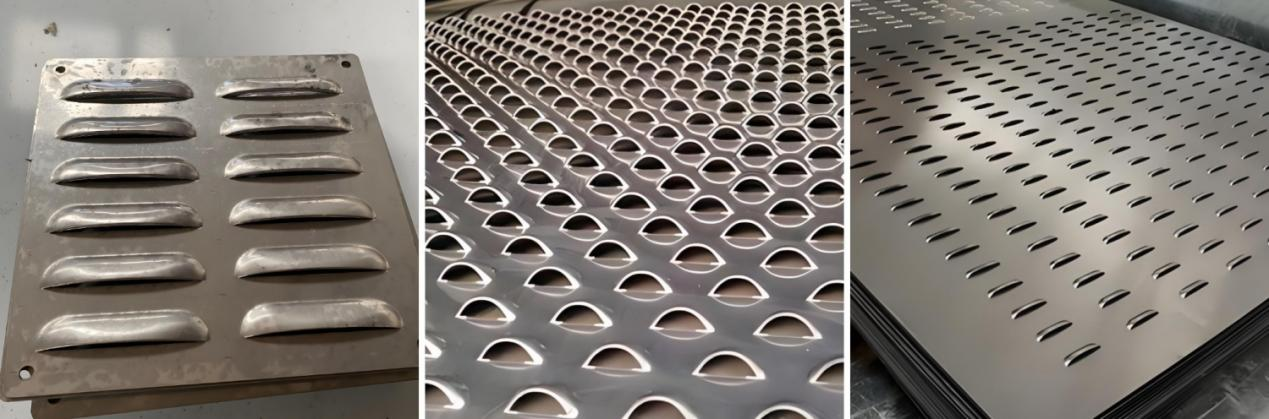

Louver Hole

Louver hole perforated steel sheet

Louver hole perforated steel sheets are typically used in applications that require heat insulation, ventilation, or privacy protection. The hole pattern is designed to resemble the slats of a louver, providing strong airflow while effectively blocking visibility. They are commonly used in building facades, air conditioning ventilation systems, shading facilities, and other areas. Louver hole perforated steel sheets not only offer functional benefits but also have high decorative value, making them widely used in architectural design. The size, spacing, and arrangement of the louver holes can be customized according to customer requirements.

Anti-Slip Hole

Anti-slip hole perforated steel sheet

Anti-slip hole perforated steel sheets are typically used in applications where increased surface friction and slip resistance are required, such as stair treads, platforms, walkways, and machinery. The hole design provides special anti-slip properties, effectively reducing the risk of slipping and ensuring safety. Anti-slip hole perforated steel sheets are widely used in industrial and construction fields, especially in high-risk environments, offering better safety and stability. The hole type, size, and arrangement of the anti-slip holes can be customized according to customer requirements.

Applications of Perforated Steel Sheets

Perforated Steel Sheets offer multiple advantages and are widely used in various industries around the world. Below are some typical application areas:

Construction Industry:

Perforated Steel Sheets are commonly used for building facades, partitions, balcony railings, and other decorative and functional purposes. They not only enhance the aesthetic of a building but also provide excellent ventilation and sunshade capabilities.

For example, in commercial buildings, residential complexes, and public facilities, Perforated Steel Sheets are used as decorative covers or curtain wall materials, creating unique visual effects.

Industrial Sector:

Perforated Steel Sheets are widely used in industrial applications such as protective covers for machinery, screens, filters, and more. They offer excellent wear resistance and strength, effectively protecting equipment from external damage.

Industries such as mining, chemical, steel, and power generation often require customized Perforated Steel Sheets for filtration and screening needs.

Transportation Infrastructure:

Perforated Steel Sheets are used extensively in road surfaces, anti-slip plates, and parking lots due to their superior compression resistance and anti-slip properties, ensuring pedestrian safety.

For instance, in airports, train stations, and parking areas, Perforated Steel Sheets are used for ground surfaces to enhance safety and reduce slipping risks.

Decorative Industry:

In the interior and exterior decoration field, Perforated Steel Sheets are popular for architectural cladding, room dividers, and decorative railings. Their unique hole designs offer both aesthetic and practical solutions, perfect for modern architectural styles.

For example, Perforated Steel Sheets are often used for ceilings, walls, and staircases in interior design, adding a contemporary touch to the space.

Environmental Protection:

Perforated Steel Sheets are used in noise barriers, air filtration systems, and wastewater treatment facilities. Due to their corrosion and wear resistance, they ensure the long-term stable operation of equipment.

Why Choose Us?

Global Supply Capability: We are not just a Chinese Perforated Steel Sheet manufacturer; we also have a global supply chain management system in place, ensuring timely deliveries to meet the needs of clients worldwide. We offer international shipping services to customers across the globe.

Strict Quality Control: We have a dedicated quality control team that rigorously checks each batch of Perforated Steel Sheets during production, ensuring consistency and high-quality standards that meet customers' requirements.

Advanced Production Technology: We use state-of-the-art CNC punching machines and laser cutting technologies to ensure precise hole sizes and smooth edges, enhancing product durability and functionality.

Environmental Sustainability: Our production processes adhere to international environmental standards, and all materials and manufacturing methods are strictly tested for environmental friendliness, ensuring that our products meet sustainability goals.

Customized Solutions: Our experienced engineering team is capable of offering tailor-made design solutions according to your specific needs. Whether it's a standard product or a special custom request, we are here to provide the best Perforated Steel Sheet solution for your project.

Contact Us

If you need custom Perforated Steel Sheets or have any questions about our products and services, feel free to contact us. Our professional team will provide free consultations and quotes, as well as comprehensive technical support for your projects. We look forward to building long-term partnerships with you and becoming your trusted Perforated Steel Sheet supplier.