Specifications and Models of Slotted Perforated Metal Sheets

We offer a variety of specifications of Slotted Perforated Metal Sheets to meet the needs of different customers. Below are the common specifications and customization options:

1. Material Options

Galvanized Steel: Suitable for general industrial and construction applications, with good corrosion resistance.

Stainless Steel: Ideal for environments requiring higher corrosion resistance and aesthetic appeal, commonly used in food processing, chemical industries, etc.

Aluminum: Lightweight, corrosion-resistant, and easily processed, perfect for projects requiring high aesthetic value.

Cold-Rolled Steel: Suitable for applications requiring higher strength, widely used in construction and transportation fields.

2. Plate Thickness

The thickness of Slotted Perforated Metal Sheets can be customized according to customer requirements. Common thickness ranges include:

0.5mm – 5mm: Suitable for light structural or decorative purposes.

5mm – 10mm: Suitable for medium-sized structures and equipment, offering greater load-bearing capacity.

10mm – 20mm: Suitable for heavy-duty applications, able to withstand high pressure and heavy loads.

3. Size Specifications

We offer flexible size options, with the most common specifications being:

Width: Typically 1 meter, 1.2 meters, and 1.5 meters, with other widths available upon request.

Length: Usually ranges from 1 meter to 4 meters, with customized lengths available based on customer needs.

4. Hole Design and Hole Size

Slotted Perforated Metal Sheets feature a unique slot hole design, and the hole size can be customized according to customer needs. The common hole size range includes:

Hole Size Range:

Small Hole Size: 1mm – 3mm, ideal for fine screening and filtration.

Medium Hole Size: 4mm – 10mm, widely used for ventilation, soundproofing, and medium-level screening.

Large Hole Size: 10mm – 20mm, used for larger particle screening and ventilation.

Hole Spacing: Can range from 2mm to 20mm, with smaller hole spacing for precise screening and larger hole spacing for screening and ventilation of larger particles.

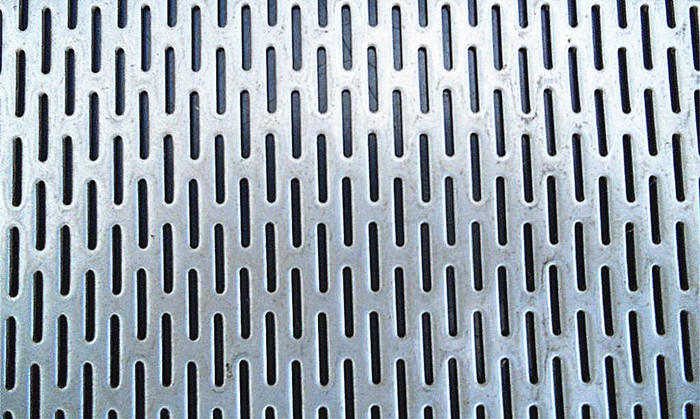

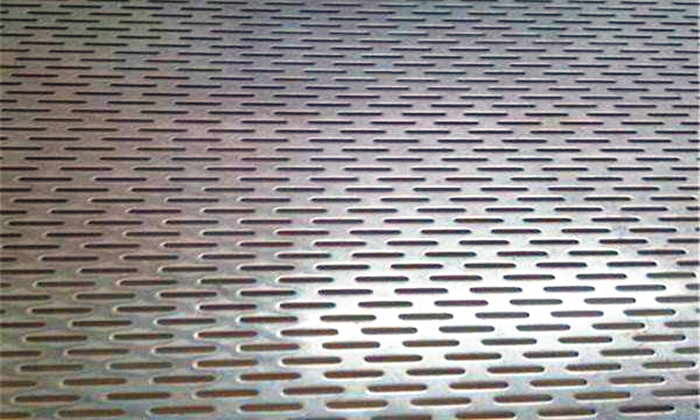

Hole Pattern:

Uniform Pattern: Suitable for general ventilation and decorative applications.

Staggered Design: Ideal for industrial screening applications to enhance screening efficiency.

5. Surface Treatment Options

We provide various surface treatments to enhance the corrosion resistance and aesthetic appeal of Slotted Perforated Metal Sheets:

Spray Paint: Suitable for steel plates, with customizable colors and good corrosion resistance.

Powder Coating: Used for galvanized steel or steel plates, providing a smooth surface and strong corrosion resistance.

Galvanizing: Increases corrosion resistance, ideal for damp or highly corrosive environments.

Polishing: Applied to stainless steel or aluminum plates to provide a smooth and polished surface, enhancing appearance.

Aluminum Anodizing: Increases surface hardness and corrosion resistance, suitable for aluminum materials.

6. Customization Services

In addition to standard specifications, we also offer comprehensive customization services to ensure that each project’s unique requirements are met:

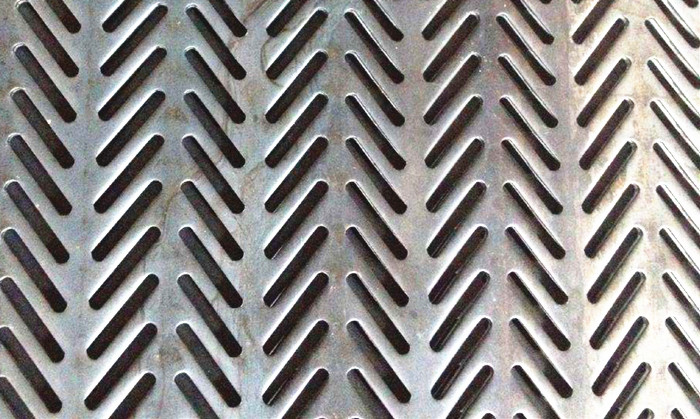

Custom Hole Designs: Besides slotted holes, we can design other hole shapes like round or square holes based on your needs.

Custom Size Options: We provide flexible customization for width, length, and thickness.

Special Materials: We can offer special metals, such as copper and alloy steel, that are resistant to high temperatures and corrosion.