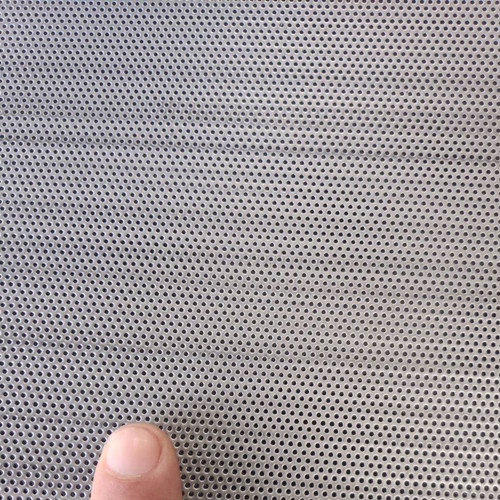

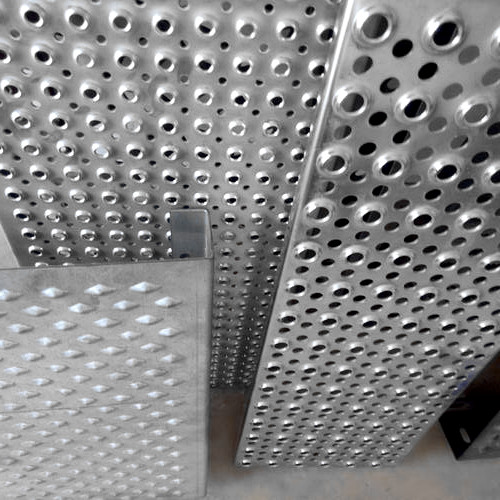

As a leading manufacturer of round hole sieve plates, we leverage advanced CNC punching technology and high-quality sheet metal materials to produce mesh screening products that meet strict quality standards. Our round hole sieve plates feature precise hole distribution, excellent screening performance, and long service life, making them widely used in the food, feed, mining, chemical, and other industries to provide efficient screening solutions.

Product Features

1. Precise Holes and Uniform Distribution

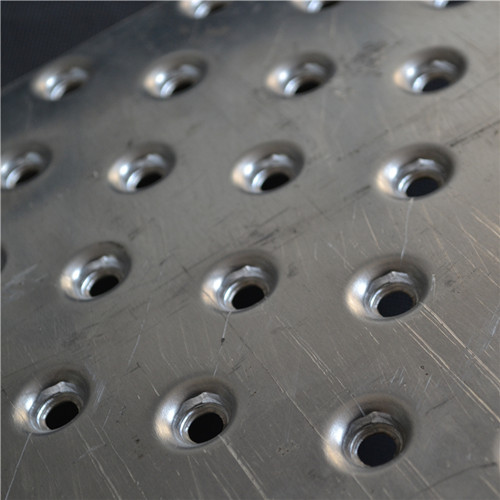

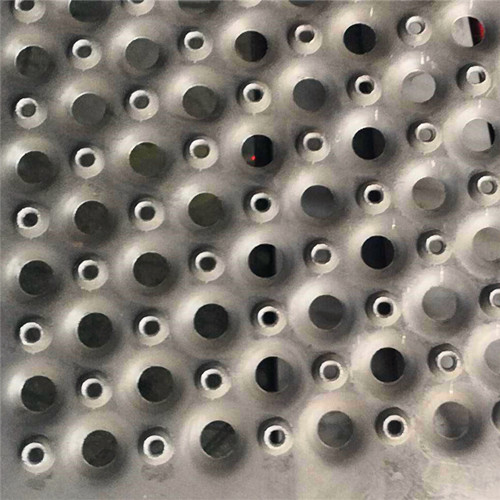

Our round hole sieve plates are processed using CNC punching technology, ensuring that each plate has consistent hole sizes and uniform hole distribution. This precise hole arrangement improves screening efficiency, minimizing material clogging during the screening process and ensuring stable screening results.

2. High Screening Precision and Long Service Life

By using high-quality materials and advanced production processes, our round hole sieve plates have excellent abrasion resistance and a long service life. Whether for high-intensity mining screening or precise food screening, they maintain excellent performance over time, reducing maintenance frequency and costs for our customers.

3. Custom Design to Meet Diverse Needs

We offer a wide range of customization options, including different materials, thicknesses, hole sizes, and dimensions for our round hole sieve plates to meet the screening needs of different industries and equipment. You simply provide the technical requirements, and we can supply plates that perfectly match your needs, improving screening efficiency and reducing the need for secondary processing.

4. Durability and Cost-Effectiveness

We are committed to providing cost-effective round hole sieve plates. Through precise manufacturing processes and stringent quality control, each plate performs steadily for a long time, reducing the extra costs associated with frequent plate replacement.

Detailed Specifications

1. Sieve Plate Materials

We offer round hole sieve plates made from various materials to suit different operating environments. Common materials include:

Cold Rolled Steel: Suitable for general industrial screening, offering good processing performance and a smooth surface.

Hot Rolled Steel: Ideal for rougher working environments, offering high strength and toughness.

Galvanized Steel: Excellent corrosion resistance, suitable for humid or chemically corrosive environments.

Manganese Steel: High hardness and excellent wear resistance, ideal for mining screening and other heavy-duty applications.

Aluminum: Lightweight material, suitable for equipment that requires lower weight.

Stainless Steel: Exceptional corrosion resistance and anti-oxidation properties, ideal for the food, chemical, and pharmaceutical industries.

2. Sieve Plate Thickness

Our round hole sieve plates are available in thicknesses ranging from 0.1mm to 20mm, allowing you to customize the plate’s strength and stability to meet the demands of various working conditions.

3. Sieve Plate Dimensions

We offer custom sizes for round hole sieve plates, with common dimensions including:

Width: Custom widths up to 1.5 meters to suit most equipment installation requirements.

Length: Custom lengths up to 4 meters, though longer sizes can also be produced upon request.

Standard Sizes: Common sizes include 1m x 2m, 1.2m x 2.4m, 1m x 1.2m, etc., with special sizes also available.

4. Hole Diameter

We can produce round hole sieve plates with hole diameters ranging from 0.2mm to 300mm, allowing for flexibility in meeting various material screening requirements.

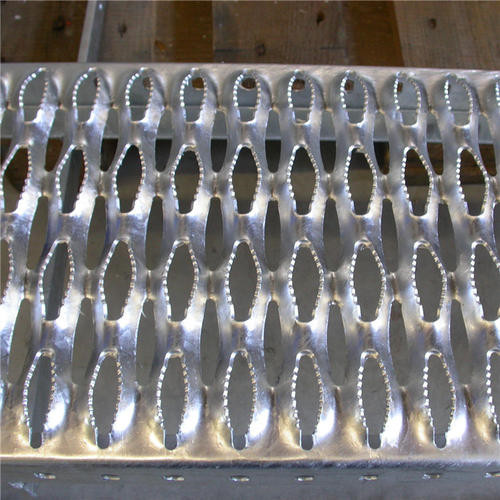

5. Hole Layout Options

The hole layout is designed based on the equipment needs and material screening characteristics. Common layouts include:

60° Staggered Layout: Improves screening efficiency and is suitable for general screening operations.

45° Staggered Layout: Reduces clogging and is ideal for screening larger particles.

90° Straight Layout: Suitable for precise screening applications, ensuring the efficient separation of fine particles.

Additionally, we can customize other layouts based on customer-specific process requirements.

Applications

Our round hole sieve plates are widely used in various industrial screening fields, including:

Food and Feed Industries: Used for grading and screening food and feed products, ensuring uniformity and quality.

Mining Industry: Used for ore sorting and screening, improving mineral utilization.

Chemical Industry: Applied for material screening and grading in chemical production, ensuring product purity.

Grinding Mill Screens: Improve grinding mill efficiency, reduce wear, and optimize the screening of grinding materials.

Other Specialized Fields: Used in construction, metallurgy, food processing, and more, offering efficient screening for diverse needs.

Custom Services and Pricing Advantages

Our round hole sieve plates are fully customized according to the customer’s specifications. We offer flexibility in terms of material, thickness, hole size, and other custom requirements. Pricing varies depending on the specifications, quantity, and material used. If you would like to receive a quote, please contact us via email with your specifications and requirements, and we will provide an accurate quote and delivery time.

Choosing our round hole sieve plates means you will receive high-precision, highly durable, and customizable screening products, along with comprehensive technical support and professional services. We are committed to providing high-quality screening solutions to customers worldwide and look forward to establishing long-term, stable partnerships. Contact us today to begin your efficient screening journey!

Round hole sieve plate Products